Overcoming Pandemic Challenges Through Solidarity

The COVID-19 pandemic continued to weigh heavily on the world in 2022. Rather than panicking over the uncertainty, the global community has adapted to coexisting with the virus.

Information disclosed reflects data collected from the reporting year.

FENC also adapted, implementing proactive management with various measures at its global locations to ensure employee safety and maintain corporate operation. Its pandemic strategies and supporting measures are tailored to the local policies, making timely adjustments to guarantee peace and safety at the workplace. Amid the zero-COVID policy in mainland China, FENC maintained the fluidity of operation, production and distribution while initiating community engagement to help the local governments combat the pandemic.

Constructing a Robust Pandemic Shield

In order to provide a safe workplace, giving employees peace of mind, FENC reinforced the promotion of health and safety implementation and prepared supporting measures for employees who contracted the virus. Measures implemented include:

Workplace implementation includes regular disinfection; installation of alcohol dispensers; space dividers and social-distancing seating arrangement at the conference rooms and canteens; take-out alternatives at the canteens. Eligible employees may apply for remote work, and the split-work model was implemented to reduce cluster infection. On-site vaccination campaigns were arranged through major hospitals.

Pandemic guidance and catchphrases were posted at the workplace and the Company’s social media website to provide timely pandemic updates.

The Company distributes pandemic supplies to employees regularly. As of the end of February 2023, 10.4 million medical masks and 230,000 COVID-19 testing kits had been distributed among FENC sites. Over 350,000 employees received COVID-19 screening and 22,000 employees received COVID-19 vaccines on site. Face shields and goggles were also distributed to employees at high risks of exposure.

FENC established the health care platform for employees to report personal and family health conditions daily through their smart phones or computers. The platform allows the Company to monitor case counts among staff and provide the care needed. While mainland China instituted the three-on-site policy, FENC production sites formed hiking, yoga and Chinese chess clubs to help boost employees’ physical and mental health. The plants also helped strengthen employees’ immune system with health supplements and pandemic supplies. When the pandemic restrictions were lifted, each employee was given seven days of pandemic leave.

Demonstrating Corporate Resilience amid the Pandemic

To control the surge in COVID-19 case counts in mainland China, several provinces and municipalities implemented complete lockdowns in 2022 to enforce the zero-COVID policy, dealing major blows to business operation. Labor shortages, supply chain disruptions and logistics meltdowns suspended production and distribution. Amid the crisis, FENC broke through, maintaining business continuity at all production sites with agility and resilience.

On March 28, 2022, the Shanghai Municipal Government issued a city-wide lockdown. OPSC immediately arranged for staff to station at the plant 24 hours a day and secured the production force. The plant launched a series of protective measures, entering the closed-loop mode and prohibiting outside entries. The plant was divided into the green zone for production, blue zone for general activities and yellow zone for the high-risk plant areas with designated staff sanitizing each zone thoroughly. OPSC made sure the plant was stocked with adequate pandemic supplies, established emergency response with contingency plans, conducted multiple drills and implemented the self-management work model. Despite the production being halted due to material shortages caused by supply chain meltdowns in mid-April, OPSC was among the first to qualify for the resumption of work and production as well as obtaining passes for material delivery trucks. Production resumed in early May, nearly two weeks ahead of the official resumption of work and production in Shanghai. The maneuvers gave FEIS the precious leeway to restore its supply chain and the overall operation.

The COVID-19 pandemic erupted in Shanghai in March 2022. To control the pandemic from all fronts, the government mandated a complete lockdown, which paralyzed the movement of people and traffic, causing material shortages that impeded production and delivery. In times of crisis, the staff of FEIS decided to hold their ground. Before the lockdown took effect, they parted with their families and were stationed at the plant. The 674 employees worked as one, overcoming obstacles and adjusting shifts to keep the production running. The plant tapped into the emergency reserve and purchased raw materials from suppliers with transportation passes. The plant also increased the export delivery and orders that could be fulfilled through water transportation to compensate for the incapacitated land freight. All units banded together, overcoming difficulties during the circulation of export documents to keep the delivery on schedule. FEIS also made sure that staff enjoyed comfort while staying at the plant and arranged pandemic training. FEIS staff also became qualified for performing the PCR testing to offer on-site screening, ensuring staff safety in all aspects.

While keeping the production line uninterrupted, FEIS mustered all strength to maintain production and distribution at the highest level possible to minimize losses induced by the lockdowns. Although business activities in Shanghai had come to a standstill, FEIS was able to maintain operation in April and May.

On July 3, 2022, the surge in COVID-19 cases in Wuxi led to increasing lockdowns and suspended public transportation, preventing employees from keeping their normal work schedule and limiting access into and out of FEIW. Entry into the plant and material delivery were restricted since the number of operating trucks was limited. While the pandemic seemed unstoppable, FEIW responded quickly to the mandates from the municipal and district governments by implementing the three-on-site policy, forming closed-loop production with 338 employees working, eating and sleeping at the plant to ensure their safety and maintaining business continuity.

As a solution to the pandemic-induced labor shortages, FEIW conducted multi-skill training, enabling staff to cover for one another when necessary to maintain production stability. To keep the delivery of goods and raw materials on schedule, the plant planned ahead and kept in close contact with the logistics companies. Raw materials were sourced either locally or from non-lockdown areas and a reserve inventory was kept as a buffer during emergency. FEIW employees persevered during this period. Amid the sizzling summer heat, they were in full protective gears, sanitizing the cargo, taking samples and loading and unloading the goods. The security staff checked the health codes, took temperature readings and performed PCR testing for all personnel entering the plant. Logistics vehicles traveling to Wuxi from mid- to high-risk areas were received by designated personnel. All production and living areas were sanitized. The well-coordinated pandemic and logistical measures made it possible for FEIW to sustain the closed-loop production for two weeks, satisfying customers with uninterrupted production and delivery.

For nearly a year since March 15, 2022, Suzhou Municipal Government performed intensive PCR Testing community by community to keep COVID-19 at bay. At OTIZ, the impact of the pandemic is far-reaching, affecting not only employee attendance, but also production scheduling, product delivery and the import and export of goods and materials because of lockdowns in Shanghai and other areas.

To maintain on-time delivery, OTIZ optimized the delivery routes, providing solutions to customers through differentiation. To mitigate business impacts caused by the pandemic, the plant adopted multi-modal freight and switched shipping options at regional boundaries to ensure uninterrupted supply of raw materials and on-time delivery. After shipping through water transportation, the cargos at the port were divided and the land freight took over. While delivery through the Suzhou distribution center was suspended during lockdown, OTIZ mobilized in-plant distribution resources to make sure the products reach their destinations. All shipments were sanitized and tested upon arrival at the plant to protect the employees. The logistic modifications introduced by OTIZ significantly reduced the impact from the pandemic.

The resurgence of the COVID-19 pandemic in Wuhan towards the end of October 2022 threw WHFE back into the closed-loop production mode in November, as required in the development zone. Employees had to station at the plant and work in shifts. The closed-loop operation had an impact on the loading efficiency and logistic timing. WHFE launched a series of measures to maintain the flow of production and distribution and a reserve system for the raw, secondary and packaging materials. The plant also made adequate preparation for employee accommodation, shift scheduling, pandemic goods and supplies as well as emergency logistics, which allowed the plant to deliver high output amid pandemic-induced labor shortages.

Defending the Public Against COVID-19

Many FENC employees in mainland China were stationed at the production sites during the lockdown to maintain business continuity. The plants also sent staff to support the anti-pandemic tasks in the frontline. Some helped the authority move pandemic goods and supplies, and some contributed locally, volunteering to fight against COVID-19 with their neighborhood associations.

Between March and June, 2022, OPSC sent eight members from its security and firefighting teams to assist with the organization effort for performing PCR testing in the development zone. Many OPSC employees also chose to volunteer at their neighborhood associations, setting an example of guarding their community by taking actions, and protecting Shanghai on behalf of OPSC.

The volunteers helped with a host of tasks. Aside from maintaining order, they also assisted with organizing the logistics for the PCR testing, unloading and distributing goods and supplies, picking up prescriptions, helping seniors and those living alone, coordinating group purchases, communicating with residents as well as providing consulting and mediating among residents.

On April 8, FEIS received the government’s call for assistance in its fight against the pandemic. Immediately, the plant recruited 35 volunteers who formed a pandemic assistance team and headed to the frontline the following day. They moved 3.84 million face masks and 2.17 million antigen test kits. With a sense of duty and responsibility, the team helped Shanghai fight against the coronavirus, working tirelessly for ten hours and resting for 20 minutes only. During the lockdown, FEIS employees could be spotted among the volunteers taking the PCR tests or performing roadside inspections in the development zone, selflessly devoting their time and effort during this trying period.

The wave of infection hit Wuxi in mid-April. On April 17, the Commerce Bureau of Xinwu District recruited volunteers from the local corporations to help battle the pandemic. FEIW mobilized its staff and five employees volunteered to answer the call for support. They headed to the frontline on April 19 and immediately started helping the authority with anti-pandemic tasks such as policy promotion and checking outside visitors. For 30 days, FEIW employees contributed to pandemic control and the society with selfless actions.

To help the community fight COVID-19, FEAZ called for its employees to join community volunteers. Between April and May, 2022, 55 employees volunteered 330 hours to help community workers perform PCR testing. In addition, to help share the heavy burden and stress from these tasks, six employees from FEAZ underwent training and became qualified for performing COVID-19 screening in Suzhou. They went on to perform COVID screening at FEAZ, serving as the bridge of communication between the government and corporations.

As the COVID-19 pandemic worsened, FENC production sites in mainland China combated the virus by complying with the local restrictions. They also contributed goods and manpower needed to fight the pandemic. On February 23, the Suzhou management division signed an agreement with Wuzhong District Charity Federation for the donation of RMB¥500,000 to fund the pandemic-fighting effort. On April 6, FEIS, OPSC and Everest Development (Shanghai) Co., Ltd. Shanghai donated RMB¥100,000 to the residents of the development zone and Haiwan Town, and RMB¥1 million to the Fengxian District Red Cross Society on April 11. The act of kindness was honored with certificates and medals. These plants embodied FENC’s philosophy, “benefitted from the society, returning benefits to the society,” fighting the pandemic alongside the local communities.

Helping Vietnam Combat COVID-19

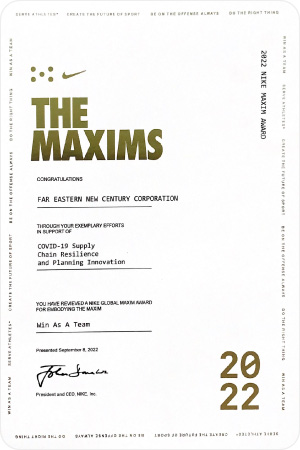

During the second half of 2021, surging COVID-19 cases prompted the authority in Vietnam to institute the “three-on-site” policy. FENC prioritized employee safety and established comprehensive emergency response and pandemic support systems, which ensured business continuity and allowed the Company to fulfill all orders delayed by the pandemic within the first quarter of 2022. FENC’s agility and resilience impressed its customer, NIKE. In its vendor’s meeting in Singapore in 2022, NIKE presented to FENC the NIKE Global MAXIM Award for Exemplary Efforts in Support of COVID-19 Supply Chain Resilience and Planning Innovation.

In Vietnam, tens of thousands of lives perished because of COVID-19, leaving thousands of children orphaned. FEPV supported Bình Dương Province and these children by making financial donations to Women International Democratic Federation. In June 2022, the plant was acknowledged with an award for this loving gesture. The donation goes towards the helping 5,444 children orphaned during the pandemic.