Instigating Production and Product Innovation

FENC develops innovative products through multiple modes to create green opportunities and enhance competitiveness.

FENC is committed to continuous improvement and growth through the relentless promotion of new product launches and the enhancement of research capabilities. This includes focusing on the development of differentiated products that are high-value, eco-friendly, and highly functional. In addition, the company is actively adopting artificial intelligence technology to improve production efficiency and management effectiveness, thereby creating a competitive edge through digitalization.

Diverse Innovative Momentum

- Dedicated R&D units: Far Eastern Group R&D Center (R&D Center) in Taiwan and Sharon Center in the U.S. are dedicated to product research and development. Synergizing their resources and expertise, the two entities focus on the development of highly specialized products as well as the advancement and applications of recycling technologies. Product categories span high-functional polyester, environmental protection and recycling, health and medical services, automotive materials as well as functional apparels. R&D Center, being the largest research center in Taiwan for polyester materials, has been an endless source of innovations for FENC.

- Product development departments within each business unit: With a diverse product lineup, FENC established product development departments under each business unit to accelerate customer engagement and product launch. The Company also founded Innovation Direct to Market (IDM) and a cross-industry technological platform to align with the R&D resources from brand customers and fast-track the commercialization of innovative products.

R&D Units at FENC

R&D Center and Sharon Center: Capturing Global Trends with Innovative Products

At R&D Center and Sharon Center, the mission is to lead the global textile industry with non-stop innovation and breakthrough through R&D. By integrating talents and resources; accelerating product development with added value; enhancing competitive edge; creating new corporate values, the Company will be known as a high tech enterprise in the polyester and textile industry.

Performance in R&D and Innovation

.png)

Unit: Number of Patents

Note:

1. R&D Center was founded in 2001.

2. FENC acquired Sharon Center in the U.S. in 2018, and the transfer of patent ownership has been ongoing. Sharon Center received approval on 559 patents. As of the end of December 2023, ownership for 483 of them has been transferred.

Funds for R&D and Innovation

Unit: NT$ Million

.png)

IDM: Accelerating Commercialization with Customer-centric Development

The world is changing at an accelerating pace. Brand owners are rolling out innovative products to win business opportunities and appeal to ultimate consumers. To pinpoint customer needs with precision, the Company integrates its R&D resources with core capabilities and established IDM in 2019, a R&D institute founded upon 7 technological platforms. IDM helps the Company to expand from the midstream polyester industry to the downstream textile apparel industry, and to accelerate the commercialization of product innovations with the design capability of COLAB.

Value: Speed、Smart、Scale、Sustainability、Innovation

Scope: 16 plants and 6 testing facilities in Taiwan, Mainland China, Vietnam and Japan.

7 Technological Platforms

1 | Polyester and PU Polymerization Develop monomers with bio-based, carbon reducing or other functional qualities that can be polymerized into PET macromolecules. |

R&D Focus Develop polyester materials that are low carbon and permanently hydrophilic with enhanced softness and low-temperature dyability. | |

2 | Modification and Synthesis for Dyes Modify disperse dyes to enhance dispersion, thermal stability and dyability. |

R&D Focus Develop solution-dyed nylon and reduce carbon footprints. | |

3 | Polyester and Nylon Polyblend Develop performance fabric added with novel ceramic additives to enhance product functions and wash durability. |

R&D Focus Develop odorless polyester, anti-bacterial polyester, hydrophobic polyester, and UV protected polyester. | |

4 | New Processing Technology for Spun Yarn Develop special functional coating on fibers to enhance product performance and wash durability. |

R&D Focus Develop hydrophobic fiber, hydrophilic fiber and profiled fiber. | |

5 | Textile Analysis and Design Pair elastic fiber with hydrophilic, hydrophobic or other functional fibers and enhance unique product features through computer jacquard loom. |

R&D Focus Develop products with wickability and thermal insulation qualities that produce low microfiber pollution and the woven-like appearance. | |

6 | Textile Coating and Laminating Apply fluoride and solvent free adhesives for coating and laminating. |

R&D Focus Develop polyurethane-reactive (PUR) adhesives and 3D stereo lamination. | |

7 | Design and Synthesis of Processing Agent Develop additives with bio-based or other functional qualities |

R&D Focus Develop bio-soaping agent, bio-reducing agent, bio-deodorant and ultra wicking. |

Special Products and Production

Reducing pollution with solution-dye nylon

IDM collaborates with FEFC and developed solution-dyed nylon. By adding color master batch during drawn work, the colors are evenly distributed on the fiber. Comparing to the conventional dyeing process, solution dye reduces GHG emissions by 60% and water consumption by 90%. Demand for chemical dyes, additives, water resources and wastewater treatment is dramatically decreased. The colors of solution-dyed nylon can be tailored to meet customers’ needs. This highly adaptive feature also reduces material costs associated with correcting color differences.

Breathing new life into scrap fabric with recycling technology

FENC has been recycling waste materials through mechanical methods without using any chemicals. The recycled materials are richly colored, hence giving remanufactured products unique color finishes without the dyeing process, which conserves energy and water. FENC has established waste recycling campaigns with brand owners to turn scrap fiber and recycled PET bottles into 100% recycled polyester. The waste materials are reborn, helping FENC fulfill its sustainable mission to reduce carbon footprints and eliminate waste.

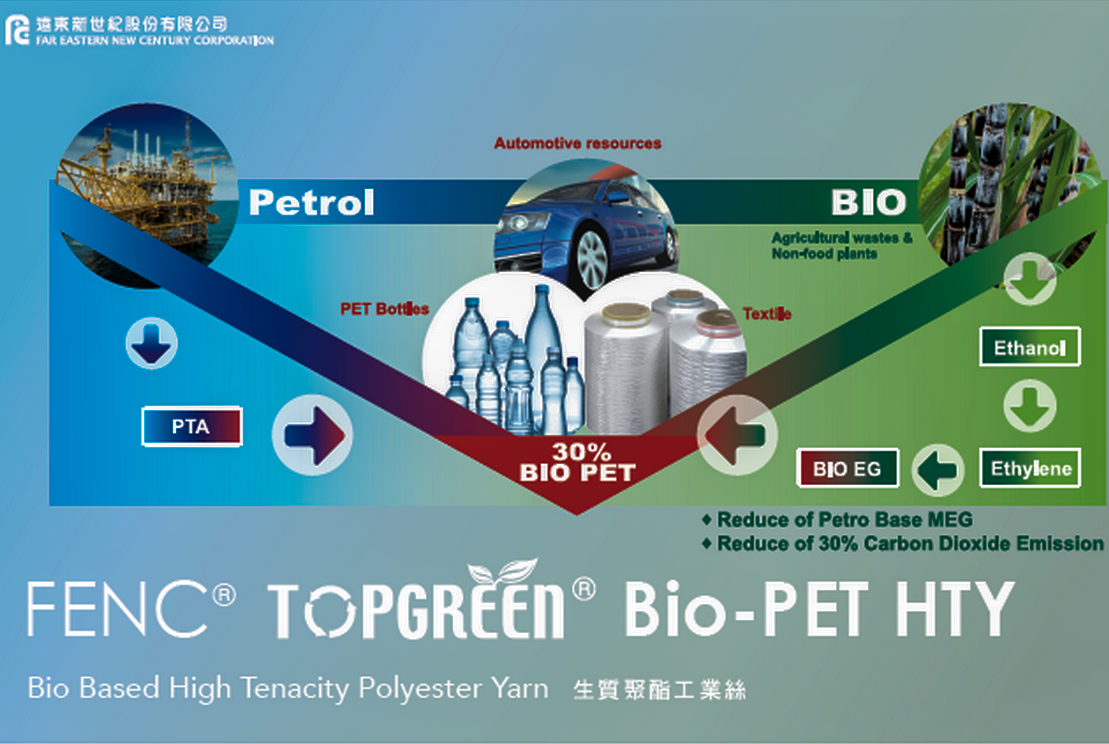

Lowering reliance on petrochemicals with new polyester processing

FENC collaborated with LanzaTech in 2019, capturing carbon by turning exhaust gas from steel mills into alcohol, which is then catalyzed into ethylene glycol that is polymerized with PTA to form PET. Comparing to the conventional approach, this new production process emits 50% less GHG and 60% less acid gas; consumes 65% less water. In 2019, this new process was responsible for the making of 3rd generation bio-based High Tenacity Yarn (bHTY). In 2020, IDM utilized this technology for polyester textured yarn and gained recognition from brand customers, effectively reducing dependence on petrochemical raw materials.