Innovative Applications x Green Raw Materials x Visionary Deployment

FENC has achieved a leading status in green polyester materials powered by the tremendous force of circularity. By leveraging its vertically integrated production network in the polyester industry and establishing inter-disciplinary technological partnerships, FENC transforms waste into quality products sourced from recycled materials, and rises as a critical player in the global circular economy.

Information disclosed reflects data collected from the reporting year.

Anchoring to its core polyester technologies, FENC has developed a wide spectrum of innovative raw materials and product applications though its alliance with value chain partners. Meanwhile, the Company is expanding the production capacity of rPET to generate growth momentum and accelerate green transformation, aiming to reach its sustainable development goals.

Innovative Applications: Expanding Core Polyester Technologies

With the resolve to promote environmental sustainability, FENC became the first in the industry to dedicate itself to the circular economy. Back in 1988, FENC founded the first PET bottle recycling plant in Taiwan as its recycling technologies continued to evolve, giving birth to high-quality rPET. With wide applications such as food packaging, non-food packaging, hygiene care textiles, home textiles, functional sportswear, shoe materials and automotive textiles, the potential is still growing. By tapping into its vertically integrated network, FENC is extending the product applications downstream to the PET film and PET sheet production. Meanwhile, the Company is working closely with value chain partners to develop more sustainable possibilities.

FENC developed the world’s first rPET surfactant through a collaboration with Oriental Union Chemical Corp. The product marks a departure from fossil-fuel-based materials by replacing the lipophilic end of the surfactant molecule with rPET. This product is first adopted by DEDA Biotech Co., Ltd. in laundry and dishwashing detergents, which are sold under the HOSAY brand. Sourced from rPET, this surfactant cuts the carbon footprint by more than 25%. Applicable for dyeing, finishing, coating and cleaning, the possibility does not end here. FENC applies its green innovation from packaging to the actual product, offering holistic circular economy solutions that will energize green transformation within the industry.

At the end of 2022, FENC became the first in Taiwan to obtain the letter of no objection from Taiwan Food and Drug Administration to produce rPET food contact materials, and the Company has been promoting the application of green products. In 2023, FENC teamed up with food packaging companies and developed packaging materials made of 30% rPET sheet, which can be used to produce salad containers in convenience stores. In March 2024, FENC collaborated with Far Eastern A-mart Co., Ltd. (a.mart) and produced 100% rPET trays for meat products, which reduce carbon emissions by 51% compared with their virgin plastic counterparts. In September 2024, FENC formed an alliance with a.mart, TOMRA Collection Solutions Taiwan Co. Ltd. and Li Tsang Plastics Co. Ltd. and launched the world's first smart recycling program for fresh food trays. With smart recycling machines, the public enjoys convenient recycling services and the waste plastic trays can be fully reused.

OTIZ made a technological breakthrough and became the first among its industry peers to transform waste PET bottles into recycled industrial yarn and tire cord fabrics. In 2021, its products were acknowledged by the global tire brand, Continental AG, and the partnership followed. As the supplier of tire cord fabrics sourced from 100% rPET, OTIZ is the first to be recognized by a tire company. The products have been commercialized and the 2024 sales doubled from the previous year. The success has attracted major tire companies from Italy, France, Japan and Sweden with multiple testing underway. In 2024, OTIZ began collaborating with Autoliv, the world's leading airbag brand. The collaboration set an industry precedence by pioneering 100% rPET airbags using chemical recycling. While demonstrating its innovative power in recycling technologies, FENC is also creating more eco-friendly solutions for automotive safety products.

Green Raw Materials: Creating Endless Circular Possibilities

FENC plays an active role in promoting applications of green raw materials, reducing carbon emissions through its reuse models. Since 1988, the Company has been converting waste PET bottles into eco-products, such as rPET chips and recycled polyester filaments. Today, FENC is the world’s largest supplier of food-grade rPET. To find solutions for the problem of textile waste, the Company is moving full force into developing textile recycling technologies, applying both chemical and mechanical recycling to convert waste textiles into recycled polyester filaments. Additionally, by capitalizing on superior R&D and production technologies, FENC is going beyond the current scope of recyclable raw materials and tackling waste electronics and factory waste gas. The goal is to reduce the reliance on raw materials sourced from fossil fuels.

Polyester textiles account for two-thirds of all polyester applications. To address the issue of textile waste, FENC has created a textile-to-textile (T2T) recycling system. Currently, FENC provides mechanical textile recycling to its brand customers consistently. Its chemical recycling system, which has a high technological threshold, was scaled at the end of 2024 with 5,000 metric tons of annual production capacity. Leveraging AI sorting and the in-house green recycling and production technologies, FENC loops waste textiles back to the source as polyester raw materials for high-quality filaments. Noticing the progress, FENC’s brand customers are booking ahead for the 2025 production with multiple products scheduled to be launched.

Waste Textiles

Automated Sorting

Chemical Reaction

Pelletizing

Recycled PET Chips

In October 2024, FENC and BenQ Materials Corp launched “e2cycle,” an innovative recycling technology that converts electronic waste into high-performance textiles. While the initial focus was the recycling of waste screen panels, e2cycle has been gradually expanded to include the recycling of computer mice, keyboards and other electronic waste. During the recycling process, electronic waste is palletized and turned into recycled materials by FENC. The recycled materials are then transformed into fabrics and films as raw materials provided for Xpore, BenQ Material Corp’s functional apparel brand. The e2cycle technology is a bridge between the textile and electronics industries, a recycling solution for electronic waste that satisfies the urgent quest for sustainable materials, turning “e-waste” to “eco-excellence.” This cross-industry collaboration has broadened the source of recycled raw materials. It is also inspiring innovative possibilities that will help FENC build a green future.

FENC converts PET bottles recycled from the ocean into sports jerseys. Among them is the ocean recycled anti-bursting jersey, a high-level product debuted in the 2022 FIFA World Cup, where it was chosen as the uniform for the 2022 Champion team, Argentina. The product went on as the uniform for team Spain, winner of the 2023 FIFA Women's World Cup, and for the third consecutive year in 2024, the jersey was favored by multiple champion teams, including team Spain during the UEFA European Football Championship, Real Madrid Club de Fútbol during the UEFA Champions League, team Argentina during the Copa América and Manchester United Football Club during the Football Association Challenge Cup. This record is the witness of FENC’s innovative application of eco-friendly materials and its commitment to sustainable development.

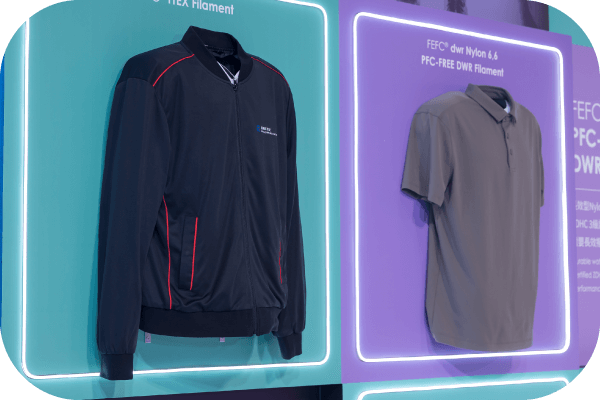

FENC was the recipient of the Red Dot Design Award in 2023 for converting recycled waste gas into low-carbon polyester. In 2024, FENC was honored yet again by the fashion industry at the iF Design Award in Germany, winning two awards with the integration of the proprietary functional design and 3D weaving technology. Standing out among over 10,000 entries from 72 countries, FENC was the only supplier to be awarded for an eco-friendly functional knitwear. This innovative product was also chosen as the material for the uniform that team Chinese Taipei wore during the opening ceremony of the 2024 Summer Olympics in Paris. Through a team effort with supply chain partners, FENC has demonstrated Taiwan's remarkable strength in creating sustainable functional textiles, setting a new benchmark where aesthetics coexists with environmental sustainability.

Visionary Deployment: Mapping the Blueprint for Green Growth

FENC is a leading enterprise in the global supply of food-grade rPET. Backed by a vertically integrated production and sales framework that spans from raw materials to the end products, its current annual global production capacity is the equivalent of converting 26 billion waste PET bottles into brand-new products. Foreseeing the business potential of green products, FENC has been accelerating the expansion of rPET production capacity in recent years. In 2024, the Himeji plant in Kansai, Japan began production, the U.S. plant, Phoenix Technologies International, L.L.C., increased its production capacity, and the new plant in Malaysia began construction with production scheduled for 2025. FENC’s Vietnam and Shanghai locations will also be seeing an increase in capacity. The efforts will continue to expand the scale of FENC’s rPET production, fueling new growth for the circular economy.

FIGP-Himeji Plant has the highest rPET production output in Japan. When its production began in February 2024, the plant encountered several challenges, such as problems with machine operation, labor shortages and surging demand for raw materials. However, thanks to close communication and coordination among all departments, the plant was able to pull through. Within three months, the operation quickly stabilized and the plant received recognitions from its customers, showing their confidence in FIGP’s products. The addition of the Himeji plant gave FIGP a boost in its business momentum, which solidified its position as the leading rPET plant in Japan.

In 2019, FENC acquired the U.S. rPET plant, Phoenix Technologies International, L.L.C. However, challenges surfaced in the form of dated equipment and inadequate maintenance. To improve its performance, FENC sent a team from Taiwan to support the retrofitting of production lines and expansion of production capacity with their experience and technical expertise. The tasks were completed successfully and production began in the first quarter of 2024. The new production lines are equipped with a continuous flake drying system and powered mainly by electricity, which reduce carbon emissions compared with the previous natural gas-powered model.

FENC is building a new rPET plant, FE GREEN PET (M) SDN BHD, in the Malaysian state of Malacca, and the groundbreaking ceremony was held on April 18, 2024. The production is scheduled to begin at the end of 2025, and the plant will increase FENC’s production of food-grade rPET with an annual production capacity of 50,000 metric tons. Once completed, the plant will form vertical integration with the existing bottling plant, maximizing synergistic effects to reinforce FENC’s regional supply chain and helping FENC deliver what the customers need.

FENC invested in building the first PET bottle remanufacturing plant in Taiwan, initiating circular economy production model with waste recycling and reuse.

FENC expanded green production into mainland China, launching rPET production at FEIS.

Far Eastern Ishizuka Green PET Corporation (FIGP) was established in Ibaraki Prefecture, Japan, specializing in the production of rPET.

Production began in Oriental Green Materials Limited’s Plant 2 in Taiwan. Manual bottle recycling is now replaced by machines, which expands the processing capacity to over 50% of waste PET bottles in Taiwan.

FENC acquired the rPET manufacturer, Phoenix Technologies International, LLC.

FIGP built the second production line.

Resin production began at Plant 2 of Oriental Green Materials Limited.

Production began at the rPET plant in the Philippines.

Production of rPET began at FIGP-Himeji Plant.

- Production of rPET with added capacity is scheduled to begin at FEIS.

- Production is scheduled to begin at the rPET plants in Vietnam and Malaysia.

Green Momentum: Achieving Excellence in Performance

World’s NO.1

in Food-Grade rPET

FENC’s contribution to waste reduction annually :

26 billion PET bottles, which may circle the earth 150 times

rPET resins cut GHG emissions by 63%. FENC’s contribution to carbon reduction annually : 870,000 tCO2e (Note1)

Equivalent to carbon absorbed by 89,000 hectares of forests.

Equivalent to annual carbon emissions from 570,000 households. (Note2)

- The comparison of GHG emissions is made between PET chips sourced from recycled PET bottles and fossil fuels using the product life cycle assessment report. The data is verified externally by TÜV Rheinland in 2017. The estimate of annual carbon reduction is based on FENC’s 2024 rPET production capacity.

- According to the 2021 Taiwan Greenhouse Gas Inventory Report, the carbon sequestration rate of each hectare of forest is 9.8 tCO2e. According to the Ministry of Economic Affairs’plan for 6.5 GW of installed solar capacity by 2020, the annual electricity consumption for each household is 3,504 kWh. The electricity carbon emission factor is 0.494 kg CO2e/kWh.

The National Brand Yushan AwardOutstanding Enterprise

Cocreating a Bright Future With a Sustainable Mindset

As the proprietor of exceptional recycling technologies and a diverse lineup of green products, FENC engages heavily in external communication to bolster partnerships. Aside from exhibitions, exchanges, promotional events, sharing sessions and special projects, the Company puts additional focus on establishing sound communication channels with local stakeholders, making concerted efforts to fulfill the sustainable development goals and strive for a bright, sustainable future.

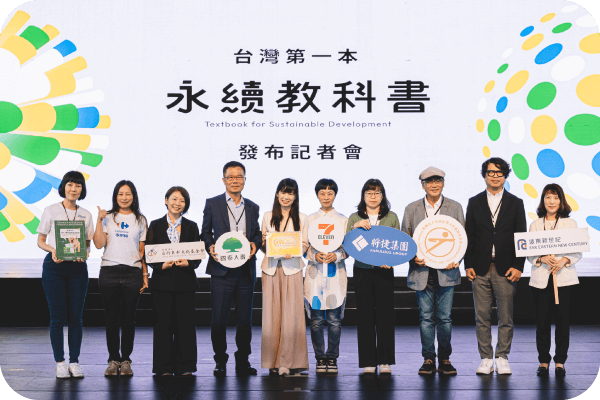

To build the bridge of sustainable education between the industry and schools, Earth Solutions and 5% Design Action have combined corporate and educational resources to create the Textbook for Sustainable Development program. These social enterprises carefully selected exemplary corporations to design the lesson plans for each of the ten major sustainability issues featured in the inaugural edition of Textbook for Sustainable Development. FENC was chosen to represent the circular economy category. Apart from joining the workshop to develop lesson plans, FENC also attended the press conference for the launch on May 3, 2024. During the event, FENC engaged teachers and principals from primary and secondary schools throughout Taiwan, using exhibits to explain its circular economy practices. The inaugural issue of Textbook for Sustainable Development was released on June 5, 2024, the World Environment Day. The publication includes FENC’s circular economy practices and the lesson plans designed for schools, which are offered to all teachers for free, helping schools create and customize sustainable lessons that suit their needs.

OGM was invited to partake in the 2024 World Oceans Day event held by the Taoyuan City Government from June 24 to July 24, 2024. During the event, OGM showcased its recycled products at Yong’an Conch Cultural Park, including functional jerseys and footwear made of waste PET bottles. The display helped the public understand that minimizing marine waste is an act of protecting marine biodiversity, and the products helped promote environmental sustainability by demonstrating that waste materials recycled from the beach can be transformed into valuables. OGM has been a member of the Blue Ocean Recycling Alliance founded by the Taoyuan City Government since 2022. The plant converts PET bottles recycled from the ocean into PET chips, which are then processed by FENC’s Filament Division to produce textile products gifted to the volunteers and participants of the beach cleaning events as a token of appreciation.

FENC was invited by the Chinese Institute of Engineers (CIE) to submit an article titled “The Circular Economy of PET: The Path to Recycling, Innovation, and Sustainability,” which was published in the June 2024 issue of the Journal of CIE. In this article, FENC provided an in-depth look into the critical role of PET in the circular economy and touched upon the recycling technologies, material innovations and sustainable applications. In July 2024, the Circular Taiwan Network invited FENC to contribute to the publication, Co-creating a Resilient Taiwan: Circular Stories. The Company shared its collaboration with the U.S. biotech company, LanzaTech. With FENC’s proprietary repolymerization technology, the partnership gave birth to the world’s first clothing item made of waste gas recycled from steel mills. This breakthrough is featured in the publication under innovation of circular materials. CIE and the Circular Taiwan Network offer free online access to these articles in the hope of promoting the circular economy by spreading the information and knowledge.

FENC is helping Yuan Ze University (YZU) implement the university social responsibility program, Green Circular Economy–Innovation and Entrepreneurship Practice Field. This three-year program, which began in August 2024, focuses on circular economy issues related to second-hand and waste clothing, such as eco-materials, fiber and clothing production, the reproduction and redesign of second-hand clothing and circular business models. FENC has been an avid participant, giving lectures on the circularity for clothing at YZU, organizing student visits to Hsinpu Chemical Fiber Plant and providing support during the campus clothing recycling event by transforming the waste garments into recycled polyester filament. Through a wide range of activities, FENC has made sustainability and circularity part of college education. Reaching an estimate of over 2,500 people in 2024, FENC is cocreating a green future with these young students.

FIGP-Himeji Plant is located in Hyogo Prefecture, Japan. To implement recycling and raise the awareness of recycling policies among local communities, the government held a seminar to discuss the recycling and reuse of PET bottles on December 20, 2024. FIGP joined the top five beverage companies in Japan to explore recycling practices during the seminar. Speaking on the topic of bottle-to-bottle recycling, FIGP shared the recycling and remanufacturing of PET bottles as well as the applications, which helped the local residents better understand the circular economy. FIGP was the only rPET manufacturer invited to this event, a sign of its significance as an incubator of the circular economy in Japan. Through the seminar, FIGP strengthened its partnerships with the Hyogo Prefectural Government and major beverage brands, and more importantly, the plant enhanced the development of circularity and sustainability in the local communities.