Creating an Intelligent Future With Technological Innovations and Applications

FENC has a comprehensive set of strategies in place to implement digital transformation, building a smart business model by incorporating AI in production, business and administrative management. An AI implementation team was established to develop smart production lines, decision optimization, human-robot collaboration, IoT and edge computing, making AI an integral component of its smart factories.

Information disclosed reflects data collected from the reporting year.

FENC is collaborating with the two tech giants and leaders in the development of AI with phased incorporation of Google Gemini and Microsoft Copilot. Their comprehensive language models and functions help FENC quickly internalize generative AI (GenAI) into its work flow, harnessing the power of technology to boost efficiency and competitiveness.

AI x Production x Safety

Hsinpu Chemical Fiber Plant has developed a smart security system that leverages the 5G and AI image recognition technologies. The system automatically analyzes image data to facilitate real-time monitoring, anomaly warning and remote control to minimize the danger of high-risk operations. The system also enhances safety by integrating visual recognition with smart wearables and optimizes the work flow and efficiency by utilizing big data to ensure quality control, worker safety and production enhancement. Its features are as follows:

Users may switch among the AI sensing modes to target specific sites and scenarios.

The system processes multiple identifications with one single lens.

With the ability to transmit image data with high speed and high quality, the 5G technology has significantly boosted the efficiency of image recognition. Upon detecting potential hazards from the images, the smart security system proceeds to quickly collect and analyze on-site production conditions and notify the management personnel for troubleshooting. Accommodating different areas and scenarios, the system is able to monitor the entire plant and minimize losses by increasing the efficiency and accuracy of risk management and control.

The smart security system is equipped with AI recognition, which automatically identifies the adequacy of staff’s personal protective equipment (PPE), determines potential hazards and issues advanced warnings to ensure workplace safety. For instance, when cutting waste materials, a procedure considered uncomplicated, less time-consuming and low-risk, operators often neglect the need to wear safety gloves and cut themselves by accident. The system may prevent such incidents by issuing warnings when standard operating procedures are not followed.

Workers may also capture on-site images in real time by wearing smart helmets. The images are transmitted to the system through a private 5G network. Integrated with the AI image recognition system, the smart helmet also determines whether the PPE is worn properly and issues warnings immediately when irregularities occur.

The smart security system screens for high-risk operations based on the frequency and level of hazards as control standards. It also performs long-term monitoring, which helps identify potentially unsafe behaviors, and provides timely response to prevent hazardous incidents and minimize risks.

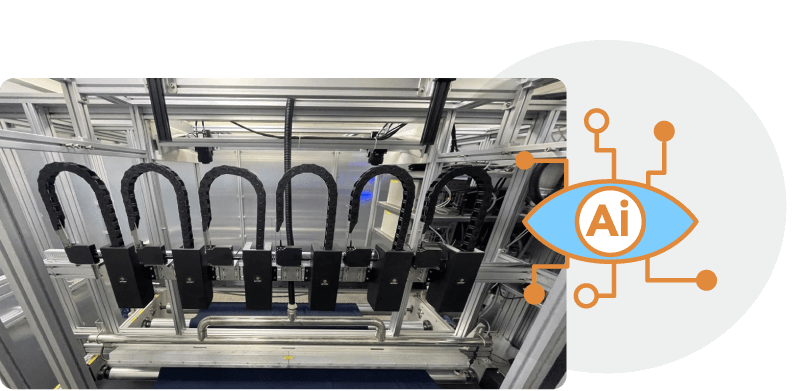

FEPV applies AI visual tools to conduct smart fabric inspection. In the past, the manual operation required employees to stop the machine, apply labels and document defects by hand, a time-consuming and labor-intensive process. The smart inspection system, on the other hand, moves 1.4 times faster. The system also delivers a 100% defect detection rate using visual AI and intelligent learning technologies, further improving product consistency and quality for customers.

OPTC introduced an automatic drone inspection system equipped with infrared detection and identification for elevated equipment. Conventional drone footages do not accommodate replays or location labeling for troubled areas. Real-time images are also unavailable during an emergency. The AI drone inspection system, however, is capable of uploading real-time footage to the cloud. After comparing AI footage with multi-temporal images, the system automatically labels the trouble spot or area with potential issues, such as insulation damage or steam leakage. The system is able to examine areas beyond the human reach and sends immediate notifications to the management for timely repair, which improves inspection efficiency and reduce labor costs.

AI x Supply Chain

Risk control is a critical link of a sustainable supply chain. To maintain supply stability, quality management and cost control, FENC created its own supply chain management platform with AI-assisted risk response. The platform alerts employees to major industry-related news, recommends freight route alternatives, makes shipping schedule forecasts and conducts safety stock analysis. When major international events occur, such as regional conflicts, natural disasters and changes in national policies, the AI assistant automatically compiles and provides related news, keeping employees informed as advanced warnings. When a potential impact on existing freight routes is detected, the system conducts analysis and provides alternative routes as contingency plans to facilitate agile response. The AI assistant also studies the shipping schedule based on the shipping history and current ship movements for inventory management.

AI x Compliance x Management

To ensure compliance for the use of GenAI across FENC, the Company established the Guidelines Governing the Use and Management of Generative AI in June 2024. The guidelines are developed by integrating global policies and trends as well as corporate needs in AI management with three major focuses, technological development and governance; risk identification and notification mechanisms; guidelines and compliance management. In August 2024, FENC’s subsidiary, Shanghai Far Eastern IT Company, obtained the certificate of ISO/IEC 42001:2023 for AI management systems, which is valid for three years. The Company is in the process of integrating the ISO/IEC 42001:2023 standards with the existing information security management system under ISO/IEC 27001, forming a seamless AI management framework.

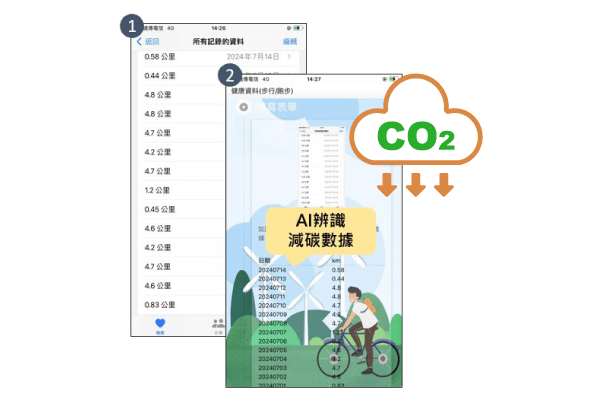

Since June 2024, the Corporate Management has been implementing a series of programs to encourage all employees to conserve energy and reduce carbon footprints, including the development of a carbon reduction passbook application. Each month, employees upload their data to the application to document carbon reduction activities, such as using public transportation, walking and running,. The AI system automatically recognizes and calculates the data, which helps employees track their carbon reduction performance.

FEPV created an agile digital mobile platform, where employees developed multiple applications using Microsoft Copilot. The applications digitize paper forms and bring the review process online to reduce labor and time. These application, which cover finance and customer management, have increased efficiency and the speed of decision-making. Meanwhile, they enhanced employee participation and a sense of accomplishment.

AI x Talent

FEFC continued its industry-academia partnership in 2024 to develop talents in lean smart management. As part of the plan to fully implement Industry 4.0 and smart manufacturing, FEFC invited 15 industry experts and professors from the Department of Industrial Engineering and Management of Yuan Ze University (YZU) as lecturers. The 2024 program, which offered 13 courses totaling 55 hours with the focus on professional knowledge in textiles and polyester, has helped 17 participating students acquire the skills in data analysis, business intelligence, big data and AI.

As the collaboration between FEFC and YZU enters its 6th year, several research projects have borne fruit. Projects which have been put to practice include AI safety alert for security personnel, 360-degree panoramic monitoring for common areas within factories, AI yarn evenness identification from mass diagram and real-time traceability for production. The integration of AI has improved production efficiency and employee safety.

To develop professional talents in the textile and polyester industries, the program offers internships to participating students to bridge the gap between industry and academia. The arrangement also helps students with career planning in advance, and three of the students have become full-time employees at FEFC. The plant will continue its talent development efforts with a forward-looking mindset and focus on pairing intelligent management with the experience in textile and polyester to help FEFC complete digital transformation and implement smart manufacturing.

FENC has been devoting efforts to systematically develop digital talents since 2023, honing employees’ AI literacy and ability to apply the technology by founding the AI Academy. Between 2023 and 2024, a total of 453 training sessions were held with 3,535 employees in participation. Details are provided in Talent Development .