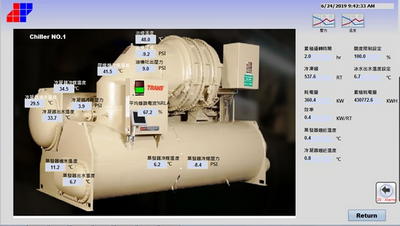

Data Visualization for Cooling System

The principle behind the operation of a cooling system is heat transfer. Residual heat carried by cooling water goes through the cooling tower and is eventually emitted into the atmosphere. The process involves the use of cooling fan and water pump, which are energy intensive. In the past, staff rely on experience and limited data to make judgement calls when operating the system. However, error in judgement tends to occur during seasons when temperature changes drastically, resulting in excessive energy consumption.

FEFC makes facility improvements by applying the concept of overall perceptions. The plant installs wet-bulb thermometer, monitors the inlet and outlet temperature at the cooling tower and incorporates smart meter, which instantly transforms data into visualized form. Staff make sound and accurate decisions based on analysis reflecting cooling effects and air conditions provided by the technology. To further reduce energy consumption, the plant switched to inverter motor for the cooling pump. Overall, this entire project conserved 1 million kWh of electricity per year, which is approximately NT$2.1 million in costs.