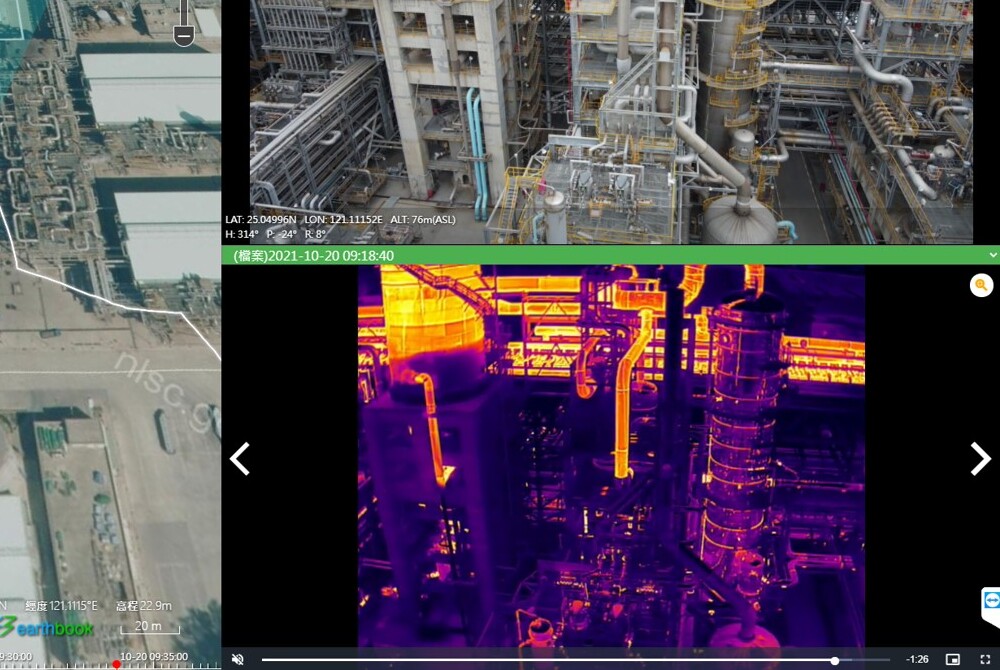

Infrared Emission Monitoring System

Low wind speed and mixing layer height are factors hindering the dissipation of air pollutants, hence worsening the air quality or causing odors that lead to grievances from local residents. Without a real-time leakage notification system, factories within the industrial park often have to take the blame from authorities. In light of this, FENC production sites incorporate the continuous emission monitoring system to obtain accurate readings on the types of possible pollutants and trends in their concentration. The data is further analyzed against wind directions to identify the source of air pollutants. In 2022, Plant 2 of OPTC adopted the environmental analysis methods accepted by the Enviornmental Protection Administration and analyzed air pollutant concentration in the vicinity of the plant premise with infrared emission monitoring system. The system collects real-time data on the types and concentration of volatile organic compounds (VOC) as well as wind directions to analyze possible sources of the VOC. When leakage occurs within the plant, data is sent back to the control center for production staff to take immediate mitigation measures. The infrared technology is capable of long-term and continuous monitoring, which helps OPTC determine the types and sources of pollutants and respond swiftly.