The World's First Commercialized Footwear With rPET Midsoles

Currently, shoes available on the market consist of a mix of materials, such as rubber soles, leather or synthetic uppers and foam midsoles, which are tightly bonded with adhesives and often end up in incinerators due to the difficulty of separation for recycling, resulting in pollution in the environment and deviation from the global carbon reduction trends. As the carbon footprints and circularity of a product’s life cycle become decisive factors in product competitiveness, footwear brands have begun the search for mono-material shoes, making shoes recyclable to embody the circular economy.

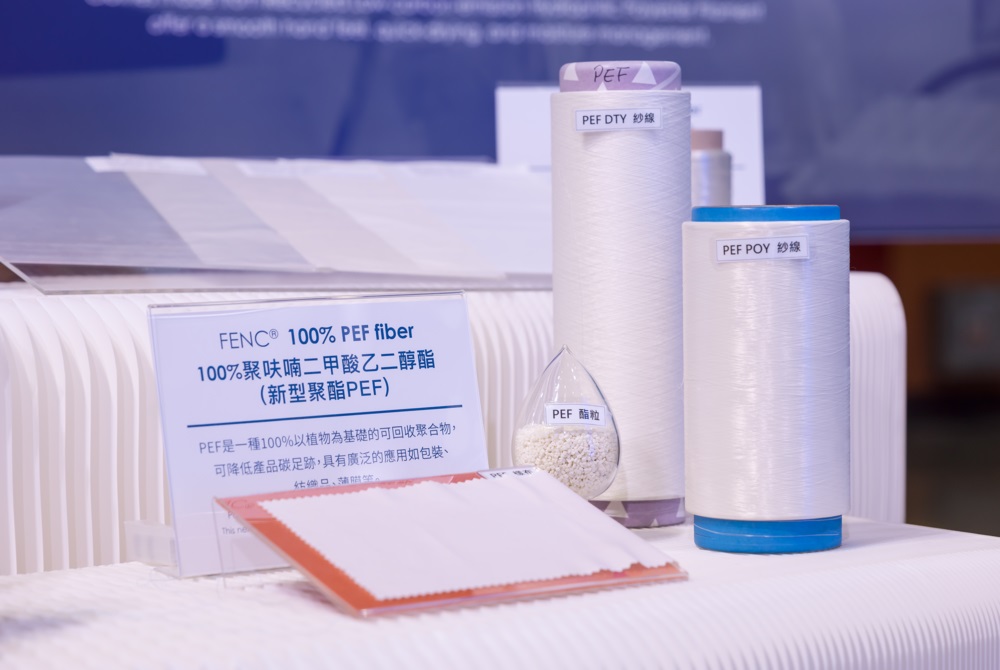

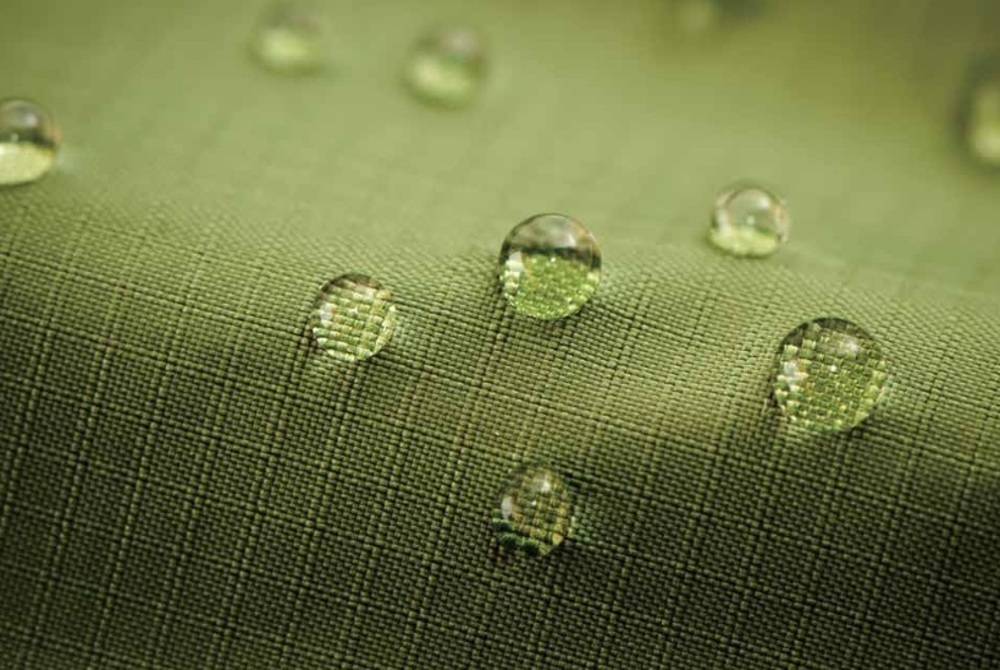

Capitalizing on its know-how in polyester synthesis, FENC has developed polyester materials of diverse specifications through polymerization and by modifying the material property to suit the various shoe components, hence creating a solution to the difficulty in separating shoe components for recycling. FENC developed uppers, laces, linings, insoles, shanks and toe cap adhesive made of rPET, and midsoles from rTPEE. Unlike the virgin TPEE produced by its industry peers, FENC’s rTPEE is made of post-consumer-recycled PET bottles, which reduces carbon emissions by 10% to 30% compared with virgin TPEE, and completes a closed loop from “post-consumer waste” to “new post-consumer products.”

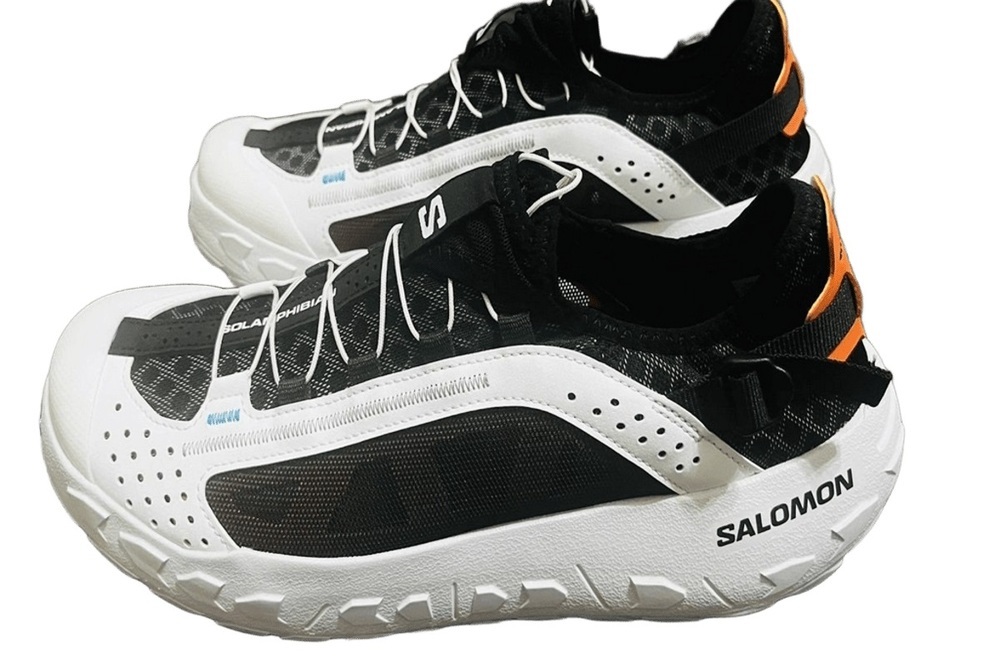

The rPET footwear material has obtained three patents and received recognitions at the ISPO Textrends Award. It has also been adopted by the mountain sports brand Salomon, which launched the world's first river trekking shoes containing materials such as 100% rPET and rTPEE in the first quarter of 2025. The recyclable materials have made total recycling a possibility in the footwear industry. FENC will expand the applications of these recycled materials for products such as casual and walking shoes to advance the sustainable development of the footwear industry.