Completing a Sustainable Loop Through Recycling

Information disclosed reflects data collected from the reporting year.

Creating Green Living through Circular Economy

It is FENC’s mission to make environmental sustainability a reality. The Company was ahead of its peers when its journey in circular economy began. As the founder of the first PET bottle recycling plant in Taiwan, the Company upgrades its recycling technologies continuously, upcycling waste materials and turning them into a wide array of high-quality rPET applications, including food and non-food packaging, functional apparel, shoe materials, home goods and automotive materials. In 2022, the Company extended its ongoing partnership with global manufacturers to develop rPET zippers and supply recycled polyester to the world.

In order to expand the scope of recycling, FENC applied its know-how in PET bottle recycling towards the recycling of textile products, breathing new life into waste textiles and clothing by making them into polyester fiber. FENC’s experience in the circular economy gave birth to FENC ®TopGreen®Recycling Solutions, a total solution for customers with wide-ranging applications, connecting recycled products to people’s lives.

Created recycled polyester filament from post-consumer PET bottles, which debuted at FIFA World Cup as national team uniforms.

Transformed waste PET bottles from the ocean into new consumer products with adidas and Parley for the Oceans.

Developed the 100% PET Closed Loop model with Coca-Cola and 7-ELEVEN in Japan.

Developed chemical recycling for polyester with CCBJI and launched the world’s first commercialized PET bottle with chemically recycled content.

- Pioneered the low-carbon polyester fabric made of waste gas with lululemon.

- Developed the tire cord fabric made of recycled polyester yarn with Continental AG, an industry breakthrough.

- Pioneered the first FIFA World Cup national team uniform with the recycled polyester filament manufactured from ocean waste PET bottles.

- Received the Accelerated Eco Best Product Award at ISPO TEXTRENDS, Sustainability & Innovation Award from ITMF and the Enterprise Asia International Innovation Awards for innovation under the product category as recognitions for its eco-friendly fabric made of the waste gas recycling and water conserving nylon production technologies.

- Supplied rPET to SPVB, which released Vietnam’s first soft drink bottle made of 100% rPET.

- Introduced the world’s first commercialized PET label-to-label application with CCBJI ad TOYOBO using chemical recycling.

- Received government approval for using recycled PET in food contact packaging, the first in Taiwan.

Supplied rPET to Coca-Cola Taiwan, which introduced the first 100% rPET water bottle produced in Taiwan - bonaqua.

Constructing the Circular Economy

FENC introduced the automated recycling machine with 7-ELEVEN Taiwan and President Packaging Ind. Corp in 2022. The public may recycle used PET bottles through the machines installed by President Packaging Ind. Corp at the 7-ELEVEN stores in northern Taiwan. After the bottles are collected by FENC, they underwent the proprietary sorting, washing, decontaminating and viscosity improvement process through its vertically integrated system. The bottles are then transformed into rPET and manufactured into 7-ELEVEN uniforms and products, completing the sustainable loop.

FIGP signed an agreement with the authority in Himeji and Ito En, Limited (Ito En) to form a 100% PET closed loop. The waste PET bottles in Himeji will be collected and sent to the Kansai plant after its inauguration in 2023. The waste bottles fulfill a closed loop when they are turned into new bottles for the Ito En products. The model was first developed in 2019 from a collaborative effort with 7-ELEVEN Japan and Coca-Cola. Waste PET bottles collected from the 350 7-ELEVEN stores in Tokyo were remanufactured into rPET and subsequently new bottles filled with beverages to be sold at 7-ELEVEN, forming a 100% PET closed loop. This model has attracted significant future partnerships with major brands and organizations.

In June 2022, FEPV signed a memorandum of understanding (MOU) with AEONMALL Vietnam Co., Ltd. (AEON) to recycle PET bottles from AEON’s retail locations and turn them into rPET as materials for new products. This partnership marks the first rPET closed-loop project in Vietnam and expanded FENC’s sustainable blueprint into the country, drawing attention for more future collaboration.

FENC was invited by the Industrial Development Bureau of the Ministry of Economic Affairs to join the program for circular supply chain transfer mechanism in 2022, forming a collaboration with IKEA and Yee Chain International Co., Ltd. to promote the first fabric-to-fabric project in Taiwan. IKEA provided fabric scraps from its retail locations, including store displays or returned goods in non-resalable condition. With FENC’s proprietary technology, the scraps went through crushing, melting, pelletizing, spinning and false twisting to transform into recycled polyester fiber, which was then made into brand-new products by FENC’s supply chain partners.

Taking International Spotlight with Recycling Know-How

FENC has amassed tremendous expertise in the development of the circular economy, lauded internationally for its green innovations. The Company’s strength lies in its vertically integrated and cross-disciplinary technological collaboration, and its core abilities to develop innovative recycling technologies. Among them are green solutions that tackle waste materials from the land, ocean and air, turning them into recycled materials that are looped back as next-generation green products, paving the way for a sustainable future.

FENC Recycling Process & Circular Economy

First in Taiwan with Approval from Ministry of Health and Welfare for Using Recycled PET in Food Container Manufacturing

The year 1988 marks the beginning of FENC’s recycling vision when it built the first PET bottle recycling plant in Taiwan. Since then, the Company has grown from the manufacturer of basic products to that of high-value ones such as food-grade packaging, functional apparel and tire applications. In May 2022, Taiwan Food and Drug Administration of the Ministry of Health and Welfare (TFDA) issued the review criteria for using recycled PET in food contact packaging, which is modeled after the European and U.S. regulations, and stipulates that recycled PET from food containers that has repalletized after washing, crushing, melting and decontaminating may be used for food contact packaging with approval.

In December 2022, FENC became the first corporation to receive the Letter of Non-Objection from TFDA for using post-consumer recycled PET in food-contact packaging. In March 2023, Coca-Cola Taiwan released the label-less bottled water, bonaqua. The product is sold in the first rPET food container produced in Taiwan using the rPET supplied by FENC. With this, the Company has provided the general consumers in Taiwan wider access to green products, bringing them closer to the circular economy.

Completing the Polyester Loop with Proprietary Recycling Technologies

With decades-long experience in the circular economy, FENC has made advancement in mechanical recycling that transforms waste PET bottles into new products. Waste polyester textiles, which are relatively simple in composition, can also be turned into new textile products for commercialization through melting and granulation or mechanical means. FENC has advanced further in recent years with the development of FENC®TopGreen®ChemCycle, an exclusive technology that utilizes depolymerization, decolorization, crystallization and purification to reduce the more complex polyester waste into rPTA, the main raw material for PET, and the quality of FENC’s rPTA is on par with that of raw materials with petroleum origin. The breakthrough also represents a sustainable alternative that bypasses fossil fuels with waste as a source material.

FENC®TopGreen®ChemCycle is patented in countries such as Taiwan, Australia and the U.S. and recognized with multiple awards, including the Excelsior Award from the 19th National Innovation Award and Enterprise Asia International Innovation Awards for innovation under the product category in 2022. The technology has also been adopted by Coca-Cola Bottlers Japan (CCBJI) to produce the first commercialized PET bottle with chemically recycled content. FENC collaborated with CCBJI and TOYOBO to complete the first label-to-label (L2L) project in the world, remanufacturing labels on PET bottles into new labels in 2022. FENC is currently developing similar applications with multiple international brands and promoting downstream applications. Already in the pipeline are production lines totaling over 1,000 metric tons in production capacity per year.

Supplying SPVB with rPET, the Raw Material of Vietnam’s First 100% rPET Soft Drink Bottle

FEPV has a long-term partnership with Suntory PepsiCo Vietnam Beverage (SPVB) and supplies PET for the production of beverage bottles. SPVB, a joint venture of Suntory and Pepsi, has started phasing into rPET for the production to reach its green goals. Since FENC’s rPET is certified by both Suntory and Pepsi, the Company became their first choice as the supplier. FENC integrated the resources from its production sites and supplied rPET from Taiwan. On April 14, 2022, SPVB launched the 330-milliliter Pepsi bottle, Vietnam’s first soft drink bottle made of 100% rPET. While this is a trend-setting move in the beverage packaging industry, FENC also successfully introduced sustainability into the consumer market.

The rPET production at FEPV is expected to begin in 2023 and the plant will form further collaborations with brand customers to localize the circular economic model.

The world is giving increasing attention to marine plastic pollution. Back in 2016, FENC partnered with adidas and the NGO, Parley for the Oceans, and transformed waste PET bottles collected from the ocean into new consumer products. Currently, FENC is the world’s largest producer of recycled ocean polyester filament. As of the end of 2022, the Company has prevented over 14,000 metric tons of plastic waste from polluting the ocean, and upcycled the waste into 78 million pairs of high-end athletic footwear and 42 million pieces of functional apparel. To make this possible, FENC needed to find a solution to address the impurities in the waste PET bottles, which added difficulties to the remanufacturing process. The Company did make a breakthrough. By integrating its resources and applying its exclusive polymerization technique, FENC created high-quality rPET resins and recycled ocean polyester filament with high tensile strength.

In 2022, FENC debuted the ocean recycled anti-bursting jersey during the FIFA World Cup as the uniform for multiple national teams. Made of FENC’s recycled ocean polyester filament, the fabric is given enhanced extensibility by FENC’s proprietary weaving technology, which allows it to withstand stringent testing for stress and bursting strength. The design is further calibrated after repeated trials by the athletes to arrive at the current version, which moves with the athletes as one. It is 12% lighter with four times the strength compared to the previous version. The jerseys have helped boosted the athletes’ performance. In 2022, nine national teams competed during the World Cup in FENC’s ocean recycled anti-bursting jerseys, and seven made it to the 16th-finals, including the reigning world champion, Argentina.

FENC collaborates with a U.S. biotech company to develop the technology to capture and upcycle waste gas from steel mills. The waste gas undergoes a special bio-fermentation process to generate ethanol, which is turned into ethylene glycol using a chemical production process and eventually into FENC®TOPGREEN®Bio3 PET through FENC’s proprietary polymerization process. In 2021, FENC expanded the application of this low-carbon polyester into textile production, delivering the world’s first recycled polyester made of industrial waste gas. A collaboration with lululemon gave birth to the world’s first apparel item made of waste gas. The breakthrough not only reduces the world’s reliance on petrochemical materials, but cuts GHG emissions during production by 30%. The material is favored by multiple international brands, including Zara, and the Company is on its way to expand product applications to industrial textiles and polyester packaging.

In 2022, FENC elevated waste gas recycling to a higher level by combining it with the nylon 66 solution-dyeing technology, creating a new breed of textile materials that embody sustainability through and through. In February 2022, the product was selected out of over 200 entries as the winner of the highest honor at ISPO TEXTRENDS, the Accelerated Eco Best Product Award. In September, the product was decorated with another major award, the Sustainability & Innovation Award from ITMF, the world’s largest professional textile organization. FENC is the only Taiwanese corporation to receive this honor. In December, the product was awarded the Enterprise Asia International Innovation Awards for innovation under the product category.

The unprecedented triple-crown win in a single year speaks to FENC’s unparalleled ability to drive sustainable innovations.

rPET Industry Status

in Food-Grade rPET

in Recycled Polyester Filament

in Recycled Ocean Polyester Filament

in rPET

Overseas Recycling and Remanufacturing Supplier Recognized by Japan Containers and Packaging Recycling Association

Product Certification

Food-Grade Approval

Recycled Content Certification

Green Mark

Driving Green Momentum to the World

FENC is the world’s largest producer of food-grade rPET and recycled ocean polyester filaments. With the second largest rPET production capacity in the world, the Company caters to all facets in life, offering a wide product spectrum that covers food, clothing, household needs and transportation. To further solidify its leading status and institute green transformation within the polyester industry, the Company launched multiple projects to expand its recycling and remanufacturing capacity at existing production sites in Taiwan, Japan and the U.S., and the nearly completed rPET plants in Vietnam, Malaysia and the Philippines, driving the green momentum throughout the world.

FENC invested in building the first PET bottle remanufacturing plant in Taiwan – Taiwan Resources Recycling Co., initiating circular economy production model with waste recycling and reuse.

FENC acquired 100% of the shares of Taiwan Recycling Corporation, which was merged into the recycling business under Oriental Resources Development Limited, and later renamed Oriental Green Materials Limited (OGM).

FENC expanded green production into mainland China, launching rPET production at FEIS.

Far Eastern Ishizuka Green PET Corporation (FIGP) was established in Ibaraki Prefecture, Japan, specializing in the production of rPET.

Production began in OGM’s Plant 2 in Taiwan. Manual bottle recycling is now replaced by machines, which expands the processing capacity to over 50% of waste PET bottles in Taiwan.

FENC acquired the rPET manufacturer, Phoenix Technologies International, LLC.

The second production line at FIGP began operation and an announcement was made to add the third production line in the Kansai region in Japan.

The production capacity of Phoenix Technologies International, LLC was expanded. Resin production began at Plant 2 of OGM.

Production at FEPV and the recycled polyester plant in the Philippines are scheduled to begin. Expansion of the Kansai plant in Japan and the U.S. production capacity is completed.

The expansion of the rPET plant in Malaysia is scheduled to be completed.

FENC’s contribution to waste reduction annually:

20 billion PET bottles, which may circle the earth 115 times.

As of the end of 2022, FENC has prevented over 14,000 metric tons of waste plastics from going into the ocean.

rPET resins made from post-consumer PET bottles cut GHG emissions by 63% compared to those of petroleum origin.

FENC’s contribution to carbon reduction annually: 580,000 tCO2e

Equivalent to carbon absorbed by 58,000 hectares of forests. Equivalent to annual carbon emissions from 320,000 households.

Note: Referring to the

data published by Taiwan Power Company

Including electricity carbon emission factor in Taiwan, carbon absorption per hectare of forests and monthly electricity consumption per household

(TCSA)

for six consecutive years

(GCSA)

World Class-Great Practice

(AREA)

FIGP is the largest rPET producer in Japan. Its plant in the Kanto region is located in Ibaraki Prefecture, where the quality of the recycled PET bales is known to be exceptional. The material can only be obtained through bidding with the Japan Containers and Packaging Recycling Association (JCPRA). To obtain the bid, FIGP fulfilled the detailed requirements set by JCPRA, including the demonstration of its abilities in raw materials storage, product sales and production. FIGP also conducted multi-lateral engagement with the authority, conveying its belief of PET bales being valuable products rather than waste. FIGP was permitted to include the bale storage capacity from adjacent areas within the same prefecture as long as the capacity met local regulations. FIGP’s persistence finally paid off in 2022 when the plant was awarded the bid. It is the largest single bid for PET bales within a six-month period in Japanese history. The quantity is equivalent to materials recycled from 90% of the families in the Kanto region, and those from 50% of all Japanese households, setting a stunning record.

Shaping the Paradigm with Sustainable Values

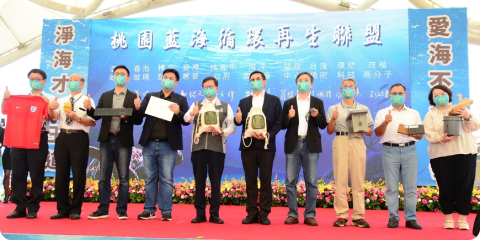

To reduce the environmental impact of waste PET bottles on marine habitat, OGM has been collaborating with Taoyuan City Government on recycling and remanufacturing PET bottles collected from the ocean since 2019. The bottles went through washing, crushing and spinning to become functional apparel. In 2022, OGM took it one step further and signed the MOU with Blue Ocean Recycling Alliance under Taoyuan City Government. Working with members in the alliance, including recyclers of Styrofoam, glass bottles and fishing nets to promote marine circular economy, OGM has established a recycling and reuse system for ocean waste, creating blue business opportunities that are shaping a high-value business model.

To strengthen trade relations between Taiwan and Central America, the Central America Trade Office arranged for the Ambassadors and Embassy staff of the Republic of Guatemala, the Republic of Honduras and Belize as well as its delegation to visit Hsinpu Chemical Fiber Plant on October 5. Representatives from FENC made a presentation on its green products as well as global promotion strategies. The plant also arranged a tour of the production line as well as its green product lineup. The visit brought FENC international fame as the guests were deeply impressed by the Company’s green innovations.

In a world threatened by the extreme conditions of climate change, corporations must seek ways to respond. FENC was invited to a forum co-hosted by Ernst & Young and the Alliance for Sustainable Development Goals to discuss net-zero opportunities and grasping sustainability and carbon management. FENC spoke on the topic of Building Low-carbon Competitiveness through Circular Economy, sharing FENC’s path to become the supplier of green materials; its green technologies, which tackle waste recycling and remanufacturing from the land, ocean and air; how the Company built low-carbon competitiveness and innovative business models through the circular economy.

FENC’s recycled ocean polyester filament made it to the 2022 FIFA World Cup as the uniform for the athletes. To share the making of these jerseys with the public, FENC accepted the invitation from the New Taipei City Government and Chinese Television System to attend the World Cup Championship celebration. FENC interacted with the public through its booth, displaying multiple World Cup jerseys that were made of recycled PET bottles from the ocean and the diverse circular economy applications. With over 5,000 participants at the event, it was an opportunity for FENC to heighten public awareness on sustainability, increase their willingness to purchase products made of recycled materials and enhance FENC’s image as a sustainable corporation.