Green Products

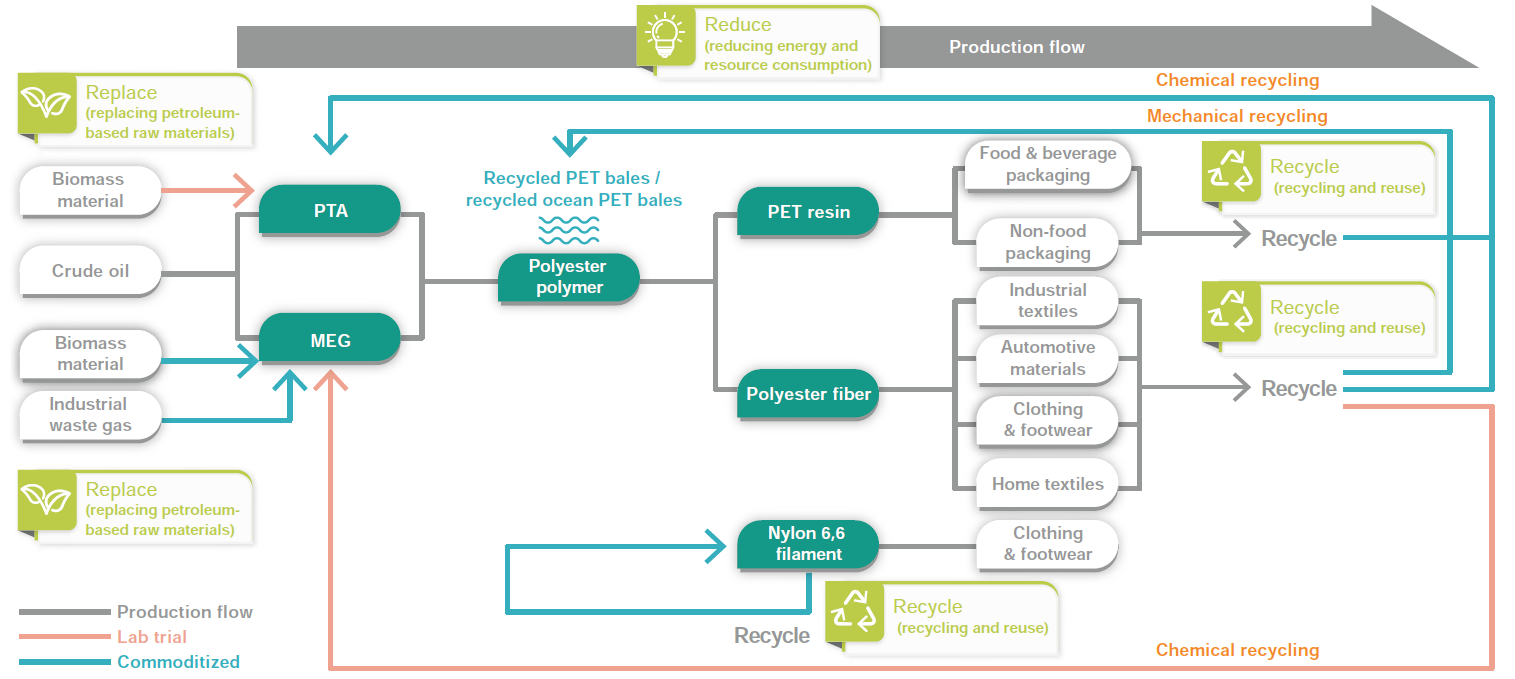

Product development focuses on the mitigation of climate change with replace, recycle and reduce at its core.

In the face of the risks and opportunities brought about by the global extreme climate, FENC applies its core competencies to the development of innovation and recycling technology, including the development of environmentally friendly rPET resins made from recycled PET bottles. Not only can it reduce GHG emissions by 63%, compared to petroleum-based PET, but also create new values by recycling and reusing waste products for food & beverage packaging, non-food packaging, functional clothing, footwear, automotive materials, and household products. FENC has been comprehensively promoting and implementing the green transformation of its products, adopting the 3R (Recycle, Replace and Reduce) strategy. In addition to "Recycle” (recycling and reuse), the company also focuses on developing green products under “Replace” (replacing petroleum-based raw materials) and “Reduce” (reducing energy and resource consumption). It leverages its 3R strategy to build low-carbon competitiveness, expand business opportunities amid climate change and reduce GHG emissions while increasing revenue growth, thus achieving the goal of mitigating climate change.

Expanding Climate Change Mitigation Products with 3R Strategy

Replace (Replacing Petroleum-Based Raw Materials)

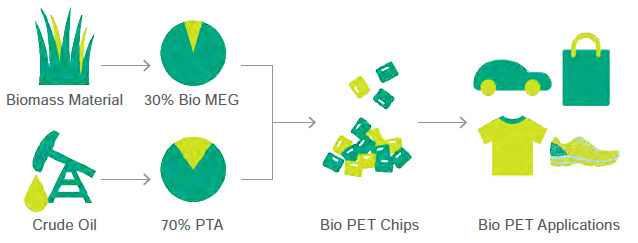

To reduce the impact of the petrochemical industry on the earth's resources and continue to contribute to the economic development of human society, FENC has long invested in the research and development of biomass materials to replace petroleum. The most representative product is bio PET and low-carbon polyester.

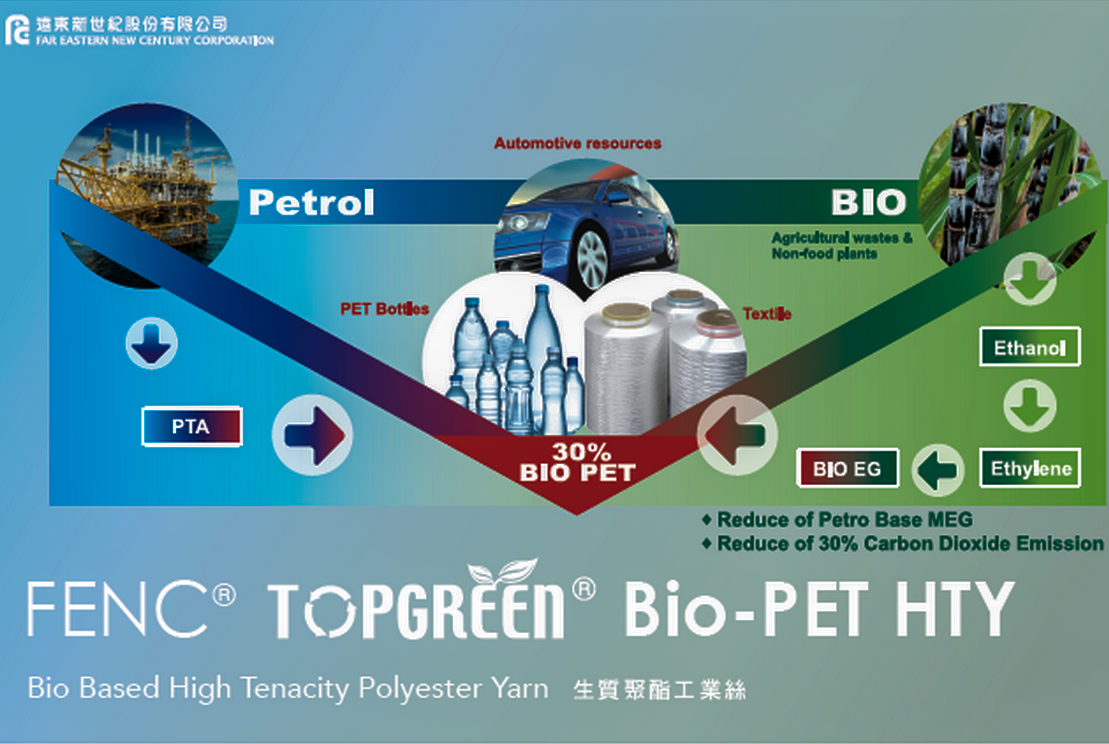

1. Bio PET

FENC, as the global leader in bio-based polyester, has successfully developed the world's first PET bottle using 100% bio-based materials and the world's first batch of 100% bio PET apparel, leveraging its 40 years of accumulated polyester synthesis technology. FENC® TOPGREEN® Bio PET, the company' s bio PET product, contains 30% bio-based ethylene glycol (bio MEG) and 70% terephthalic acid (PTA) from petrochemical raw materials. After several years of research and development, bio MEG has become economically viable, with raw materials sourced from non-food grade plants, to avoid competition with food sources and at the same time reduce dependence on petroleum.

FENC® TOPGREEN® Bio PET

2. Low-Carbon PET

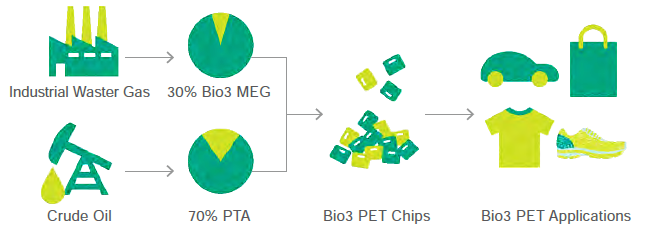

FENC has partnered with a U.S. biotech company to develop the latest technology FENC® TOPGREEN® Bio3 PET, using carbon capture and utilization technology to gradually convert industrial waste gas into ethylene glycol as raw material for low-carbon polyester filament to replace petrochemical raw materials. This novel raw material not only maintains the same characteristics and properties as petrochemical products, but also reduces GHG emissions by 30% compared to petroleum-based polyester, demonstrating outstanding effect in carbon reduction.

FENC® TOPGREEN® Bio3 PET

Recycle (Recycling and Reuse)

By cutting down waste, the global GHG emitted from waste treatment process can be effectively reduced. FENC has been deeply involved in the recycling industry for more than 30 years and has become a global leader in recycling polyester. The most representative products include rPET and its applications, as well as fabrics recycled polyester developed in recent years. In addition to the mechanical recycling technology, FENC has also adopted the more difficult polyester chemical recycling technology to separate waste polyester products mixed with other components through chemical processes, followed by polymerization and other processes to produce new polyester products.

1. Recycled PET

Using recycled PET bottles as raw materials to be further treated through processes such as crushing, cleaning, decomposition, polymerization, and granulation can not only reduce the consumption of petroleum in polyester production process, but also can cut down resource consumption, and further promote resource recycling and reuse. Polyester resins made from recycled PET bottles can reduce GHG emissions by 63% compared to conventional polyester resins derived from petroleum. Based on the production scale of FENC, the estimation is equivalent to an annual carbon reduction contribution of 650,000 tCO2e. This has a significant impact on carbon reduction throughout the entire supply chain, particularly on the client side.

2. Recycled Nylon 6,6 Filament

In response to sustainable development trends and energy-saving and carbon reduction policies, FEFC has been developing recycled filaments since 2014. It uses waste fiber and waste blocks from its own spinning process as raw materials, which are then recycled, sorted and processed through filtering and re-pelletized to produce nylon resins that can be remelted and spun into new fibers. This recycling process can eliminate the polymerization process, thus reducing energy consumption and CO2 emissions by around 70%, creating environmental benefits of energy saving and carbon reduction.

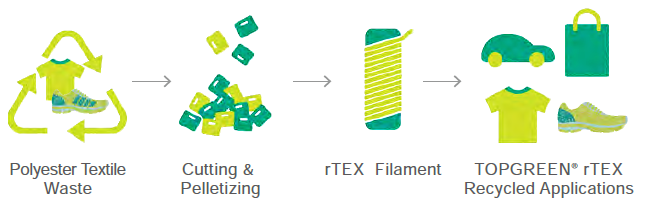

3. rTEX Filament

Recycled filaments made from waste polyester textiles as raw materials, processed through crushing, melting, granulating, drawing and false twisting, are not only produced in an environmentally friendly process and made from sustainable materials, but also provide a solution for the recycling and reuse of waste textiles.

FENC® TOPGREEN® rTEX Filament

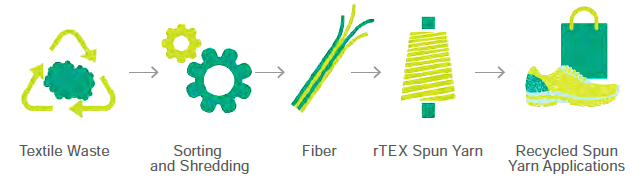

4. rTEX Spun Yarn

By recycling and reusing waste textile fabrics through physical and mechanical processing, textile waste can be converted into 100% recycled short staple yarn without the need for dyeing, avoiding the use of chemical dyes. This not only gives new life to the waste fabrics, but also embodies the concept of environmental sustainability.

FENC® TOPGREEN® rTEX Spun Yarn

5. FENC® TopGreen® rTEX Chemical Recycling

Polyester textiles account for 2/3 of all polyester applications. To address the difficulty of recycling textile waste, FENC focuses its R&D efforts on the development of textile recycling technologies. By incorporating both chemical and mechanical recycling, the Company developed the recycled fiber, FENC® TOPGREEN® rTEX. Chemical recycling, a recycling approach with high technological thresholds, is effective in processing waste textiles containing a complex mix of materials and colors. The pilot plant for the chemical recycling segment of FENC® TOPGREEN® rTEX is scheduled to be completed in 2024. Its commercialization and applications will be expanded to meet customer needs and sustainability development goals.

FENC® TopGreen® rTEX Chemical Recycling

.png)

Reduce (Reducing Energy and Resource Consumption)

FENC is also actively improving the efficiency of energy resource utilization in the value chain, reducing energy consumption in the production, processing, distribution, and raw material usage to cut down its products' GHG emissions.

1. Fast Reheat and Energy-Saving PET Resin

The energy-saving PET resins are produced by adding the far-infrared (FIR) heat in the polymerization process. Far-infrared (FIR) heat emitted by quartz lamp tubes can be absorbed effectively during the PET blowing process, improving blowing efficiency by 20-30% for FENC' s customers.

2. Refillable Bottle

The manufacturing process increases the thickness of bottle body, allowing it to be recycled and filled more than 30 times. This reduces resource consumption and the use of disposable packaging materials, thereby enhancing environmental benefits.

3. Lightweight Preform

By adjusting the process and raw materials, the stability of bottle blowing production is improved, and the thickness of PET preforms is substantially reduced. This not only cuts down raw materials used, but also reduces the weight of preforms. The weight reduction of preforms of different capacities ranges from 10-20%, achieving environmental benefits of less resource use and low carbon emissions from transportation throughout the product' s life cycle.

4. EZ Dyed CD Filament

This is a low-temperature dyeing process to render bright colors and effectively save energy at the same time. It can be used for materials suitable for low-temperature dyeing such as cotton, wool, nylon, etc.

5. Dope Dyed Filament

Color particles are added during the spinning process to reduce the use of chemical dyes, auxiliaries, wastewater treatment and toxic substances. This can substantially reduce water use, energy consumption, and CO2 emissions. Dope dyed filament is a new generation of eco-friendly and energy-saving fibers with bright colors and excellent light and wash fastness.

6. Digital Print

Different from traditional paper printing, this technology can directly print on various kinds of fabrics, with a faster speed and no limit on colors and patterns, to deliver colorful and detailed rendering. Compared to traditional printing processes, it requires less water, effectively mitigates wastewater problem, and conforms to the market trend of environmentally friendly production.

7. Sustainable Cotton

Compared to traditional cotton, sustainable cotton is grown using sustainable and scientifically based farming methods, which can not only reduce water use and GHG emissions, but also improve soil health and enhance biodiversity.