Water Resources Management

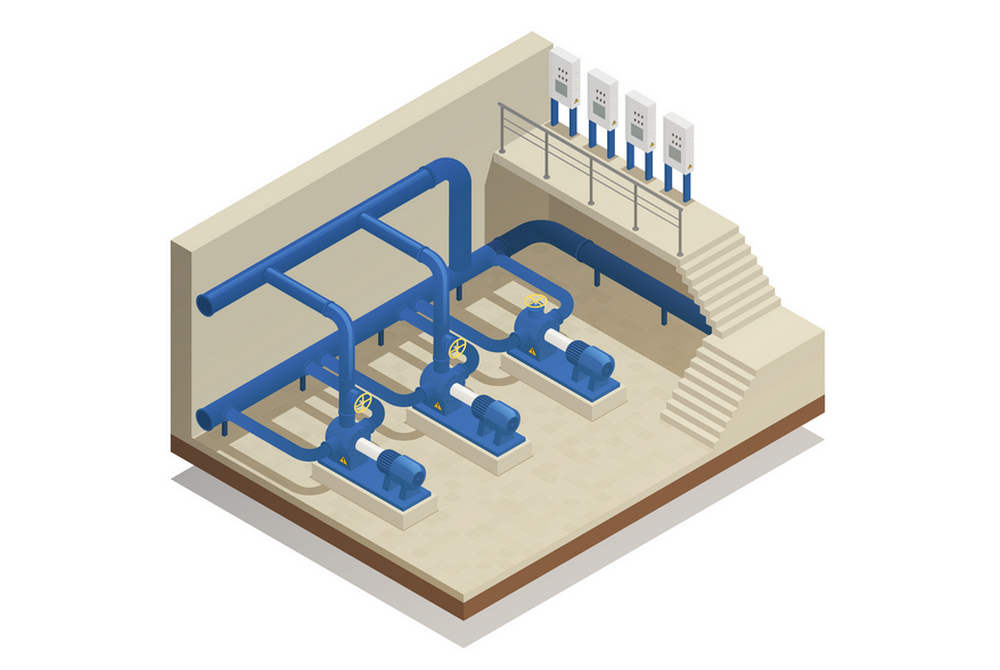

Consistently innovates and upgrades wastewater treatment facilities to reduce wastewater discharge.

FENC has adopted a three-pronged approach for effluent management methods and implementation plan:

1. Effluent source management: Modify and optimize the production process to reduce oil and surfactant discharge.

2. Treatment efficiency management: Gradually replace outdated equipment, regularly replace filter membranes, and establish real-time management through an intelligent central control system to adjust the operating parameters of wastewater treatment equipment in synchronization with process changes.

3. Environmental impact management: Continue to build wastewater treatment facilities that reduce noise, odor and pollution to improve the quantity of recycled water and to actualize the recycling and reuse of natural resources.

The Company has a comprehensive wastewater treatment standards and SOP in place to treat the wastewater discharge. With established treatment procedure, wastewater quality is regularly tested for pollutants to ensure compliance with governmental standards. The Company also obtains industrial wastewater discharge permit prior to discharging into water bodies where permitted. Wastewater from FENC is not utilized by any other organizations.

Beginning on February 1, 2023, Taiwanese government started issuing water conservation charges for users consuming over 9,000 kiloliters of water during dry seasons. Considering that seven of its production sites in Taiwan will be subject to this policy, FENC will continue to implement water conservation measures, reuse reclaimed water and increase water recycling rates to obtain favorable conditions for reduced charges or deduction.

Total effluent was down by 8% in 2022 compared with the previous year while effluent per unit of production increased by 3%. The main contributing factor is lower production. FENC plans to continue adding effluent recycling and reuse systems to increase water efficiency per unit of production.

Management Guidelines and Measures

Water Discharge per Unit of Production

Unit: kiloliter / metric ton of production

Water Discharge in 2022

Total effluent was down by 8% in 2022 compared with the previous year while effluent per unit of production increased by 3%. The main contributing factor is lower production. FENC plans to continue adding effluent recycling and reuse systems to increase water efficiency per unit of production.

Wastewater Discharge

Unit: megaliter

Water discharge by TDS | Water discharge by destination | ||||||

Freshwater (≤ 1,000 mg/L | Other water ( > 1,000 mg/L | Surface water | Off-site water treatment | Beneficial / other use | Total discharge water | ||

| Petrochemical | 2020 | 0 | 6,045 | 1,555 | 4,490 | 0 | 6,045 |

| 2021 | 0 | 6,211 | 1,253 | 4,784 | 174 | 6,211 | |

| 2022 | 0 | 6,252 | 1,228 | 4,855 | 169 | 6,252 | |

| Polyester | 2020 | 944 | 1,932 | 1,857 | 1,019 | 0 | 2,876 |

| 2021 | 966 | 2,074 | 2,000 | 1,040 | 0 | 3,040 | |

| 2022 | 889 | 1,817 | 1,703 | 1,003 | 0 | 2,706 | |

| Textile | 2020 | 727 | 2,339 | 27 | 3,039 | 0 | 3,066 |

| 2021 | 847 | 2,480 | 34 | 3,293 | 0 | 3,327 | |

| 2022 | 827 | 1,698 | 32 | 2,493 | 0 | 2,525 | |

| Total | 2020 | 1,671 | 10,316 | 3,439 | 8,548 | 0 | 11,987 |

| 2021 | 1,813 | 10,765 | 3,287 | 9,117 | 174 | 12,578 | |

| 2022 | 1,716 | 9,767 | 2,963 | 8,351 | 169 | 11,483 | |

Note: 1. FENC does not discharge effluent directly to the seawater or groundwater / well water. Please refer to the table, Effluent Treatment Methods and Final Discharge Destination. |

Effluents Treatment and Final Discharge Destination

Business | Production Site | Effluents Treatment and Final Discharge Destination |

Petrochemical | OPTC | Wastewater at Plant 1 of OPTC goes through biotreatment, including anaerobic and super deep aeration treatments and discharged into Shulin River once it meets the effluent standards. At Plant 2 of OPTC, wastewater goes through biotreatment, including anaerobic and high-efficiency aeration treatments. Once reaching the sewage connection standards, the wastewater is discharged into the sewage system operational center in Kuanyin Industrial Park and finally discharged into Shulin River. |

OPSC | Wastewater is treated internally until reaching the required standards, and then discharged through the municipal pipelines to Fengxian District East Wastewater Treatment Plant. Once fully treated, the wastewater is discharged into Hangzhou Bay. | |

Polyester | Hsinpu Chemical Fiber Plant | Wastewater goes through biotreatment internally. Once reaching effluent standards, it is discharged into Fengshan River. |

Kuanyin Chemical Fiber Plant | Wastewater goes through biotreatment internally. Once reaching effluent standards, it is discharged into Shulin River. | |

FEFC | Industrial and domestic wastewater goes through biotreatment (contact oxidation) and sedimentation internally. Once the water reaches the effluent standards, it is discharged into Shulin River. | |

OGM | Wastewater is first treated in house. Once reaching the effluent standards, it is discharged to the wastewater treatment plant in the industrial park for further treatment, and then discharged into Shulin and Dajue Rivers. | |

FEIS | Wastewater is treated internally until reaching the required standards, and then discharged through the municipal pipelines to Fengxian District East Wastewater Treatment Plant. Once fully treated, the wastewater is discharged into Hangzhou Bay. | |

WHFE | Treated in the internal wastewater treatment facility first, the wastewater then goes through the municipal wastewater treatment facility. Once fully treated, it is discharged into the Yangtze River. | |

FEPV | Wastewater is treated internally until reaching the required standards (through online testing), and then discharged into ecological pond no. 1 in Bau Bang Industrial Park. Once fully treated, the water is discharged to Thị Tính River. | |

FIGP | Wastewater is treated internally until reaching the required standards and then discharged to Tone River. | |

APG Polytech | Wastewater is treated internally until reaching the required standards and then discharged to Ohio River. | |

Textile | Kuanyin Dyeing and Finishing Plant | Wastewater is treated in house, discharged to the wastewater treatment plant in the industrial park for further treatment, and then discharged into Shulin River. |

Hukou Mill | Wastewater goes through biotreatment (oxidation and aeration) internally and then discharged into Desheng River. | |

OTIZ | Wastewater is treated internally until reaching the required standards, and then discharged through municipal pipelines to Hedong Wastewater Treatment Plant. Once fully treated, the water is discharged to the Jing-Hang Grand Canal. | |

FEIW | Wastewater goes through Wuxi municipal sewage pipelines to the wastewater treatment facility. Once treated, the water is discharged into the Jing-Hang Grand Canal. | |

FEDZ | Wastewater is treated internally until reaching the required standards, and then discharged through municipal pipelines to Hedong Wastewater Treatment Plant. Once fully treated, the water is discharged to the Jing-Hang Grand Canal. | |

FEAZ | Wastewater is treated internally until reaching the required standards, and then discharged through municipal pipelines to Chengnan Wastewater Treatment Plant. Once fully treated, the water is discharged to the Jing-Hang Grand Canal. | |

FEAV | Wastewater is treated at the treatment center within the industrial park and then discharged to Saigon River. | |

FENV | Wastewater is treated at the treatment center within the industrial park and then discharged to Song Be River. | |

FEPV | Wastewater is treated internally until reaching the required standards (online monitoring), discharged to the wastewater treatment plant in the the No. 1 ecological pond of Baopeng Industrial Zone, and finally discharged to the Thị Tính River. |

| Note: 1. There is no significant impact from wastewater discharge on the water bodies and related habitat. 2. Wastewater at OPSC includes wastewater from the manufacturing process, domestic wastewater, lab wastewater and wastewater from the cooling tower. Wastewater at Hsinpu Chemical Fiber Plant, Kuanyin Chemical Fiber Plant, FEFC and FEIS is from the manufacturing process, cooling tower, domestic wastewater and cleaning water. Wastewater at OGM, WHFE, FEDZ the polyester plant of FEPV and APG Polytech is from the manufacturing process, domestic wastewater and lab wastewater. Wastewater at Kuanyin Dyeing and Finishing Plant, OTIZ and FENV is from the manufacturing process and domestic wastewater. Wastewater at OPTC is from the manufacturing process and the cooling tower. Wastewater at Hukou Mill, FEIW, FEAZ and FEAV is from domestic wastewater. Wastewater at the textile plant of FEPV and FIGP is from manufacturing process. 3. Total wastewater volume includes domestic wastewater. The domestic wastewater was 634 megaliters in 2020, 739 megaliters in 2021 and 867 megaliters in 2022. 4. Calculation of wastewater at Hukou Mill also includes the biomedical business unit of Oriental Resources Development Limited. 5. There is no significant impact caused by the effluent on water bodies and adjacent habitats. 6. Minimum wastewater discharge standards have been established at all production sites in accordance with local regulations and industry characteristics. 7. The discharge water treatment method and final discharge location have not changed in the past three years. |

System Establishment and Management

OPSC installed online water quality analyzers at the effluent outlets. The devices, which are connected to the network of local environmental protection authority, monitor the water quality in real time. With daily sampling and analysis at multiple points and regular time, anomalies could be addressed immediately. When the water quality fails to meet the standards, connection to discharge pipelines is cut off and the water is returned to the treatment facility. The occurrence would be reviewed to identify the cause and improvement.

In addition, storm sewer inlets are controlled based on weather conditions, open on rainy days and closed on sunny days. Water samples are collected and analyzed when the water level in the retention pond is high. The water is discharged when water quality standards are met. Otherwise, the water is to be treated at the wastewater treatment plant.

The operational department at FEFC inspects wastewater management daily, taking three weekly samples at the wastewater treatment plant, conducting semi-annual water quality testing through external agencies and holding regular testing training to prevent any negative effects to the receiving water body of effluent discharged from the plant.

Incorporation of Innovation Technology and Facility

FENC continues to incorporate innovative effluent treatment equipment and reduce effluent discharge. Kuanyin Chemical Fiber Plant monitors conductivity at the cooling tower with a conductivity controller, which remotely controls the solenoid valve at the tower. The device provides a time- and effort-saving alternative to manually operating the valve on site and reduces excess discharge and water waste.

The polyester plant of FEPV installed an online effluent chemical oxygen demand (COD) monitor using optical and closed reflux methods. When the readings exceed the permitted level, the effluent will be automatically pumped to a temporary pond. The effluent is to be discharged only after the anomaly is addressed, the system is functioning normally, and the governmental standards are met.

Value Chain Collaboration

OPSC engaged with suppliers of water treatment chemicals in 2022 and discussed approaches to prolong the duration of RO membranes to increase reclaimed water volume.