Environmental Management

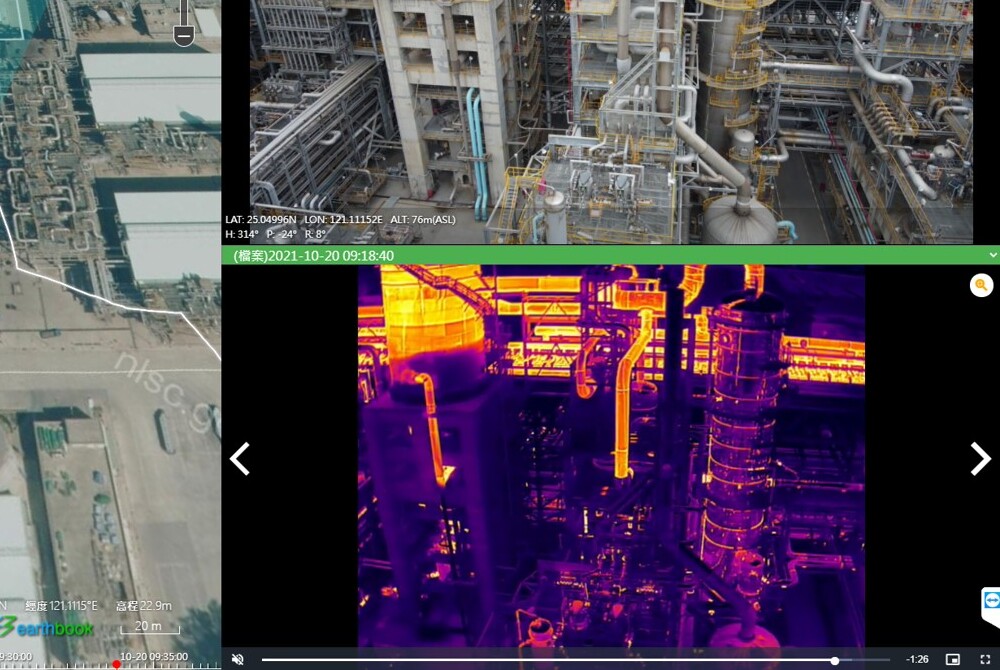

Continuously to introduce new technology on air pollution prevention and control, and examines existing facilities and production process regularly. To ensure regulatory compliance and help reach reduction targets.

FENC adopts a stream of technologies to prevent and control air pollution. Regular reviews are conducted over existing facilities and production flow to ensure compliance with all emission standards. The Company uses online monitoring systems and equipment to record real-time conditions and keep tabs on any unusual occurrences with a priority focus on mitigating environmental risks in production design and minimizing pollution caused by the production process. All pollutant emission data is in compliance with regulatory standards and filed with the authority.

Air Pollution Management Guidelines and Measures

.png)

Air Pollution Emissions in 2024

.png)

Air Pollution Emissions per Unit of Production

Unit: kg / metric ton of production

.png)

Air Pollutant Emissions per Unit of Production in 2024

Unit: kg / metric ton of production

NOx | SOx | POP | VOC | HAP | Particulate Pollutants | Total | |

Petrochemical | 0.07 | 0.03 | 0.00 | 0.03 | 0.00 | 0.01 | 0.14 |

Polyester | 0.05 | 0.06 | 0.00002 | 0.05 | 0.0007 | 0.01 | 0.17 |

Textile | 0.32 | 0.24 | 0.05 | 0.01 | 0.00 | 0.10 | 0.67 |

Production Business | 0.07 | 0.06 | 0.00001 | 0.05 | 0.0005 | 0.01 | 0.19 |

| Note: The Textile Business does not include FEAZ, FEAV and FENV. |

In 2024, the total air pollutant emission dropped by 11% compared with the previous year. The air pollutant emission per unit of production stayed on par with 2023. Efforts will continue to enhance the equipment, monitoring and efficiency of air pollution prevention and control.

Air Pollution Emissions

Unit: metric ton

NOx | SOx | POP | VOC | HAP | Particulate Pollutants | Total | ||

Petrochemical | 2021 | 217 | 80 | 0 | 160 | 0 | 17 | 474 |

2022 | 172 | 72 | 0 | 116 | 0 | 15 | 375 | |

2023 | 110 | 75 | 0 | 106 | 0 | 8 | 299 | |

2024 | 100 | 38 | 0 | 38 | 0 | 7 | 183 | |

Polyester | 2021 | 470 | 216 | 0 | 302 | 3 | 46 | 1,037 |

2022 | 426 | 223 | 0 | 292 | 3 | 37 | 981 | |

2023 | 295 | 283 | 0.07 | 257 | 3 | 37 | 875 | |

2024 | 253 | 269 | 0.08 | 263 | 3 | 33 | 821 | |

Textile | 2021 | 123 | 69 | 0 | 28 | 0 | 19 | 239 |

2022 | 101 | 75 | 0 | 22 | 0 | 37 | 235 | |

2023 | 115 | 90 | 0 | 19 | 0 | 32 | 256 | |

2024 | 124 | 93 | 0 | 7 | 0 | 38 | 262 | |

Total | 2021 | 810 | 365 | 0 | 490 | 3 | 82 | 1,750 |

2022 | 699 | 370 | 0 | 430 | 3 | 89 | 1,591 | |

2023 | 520 | 448 | 0.07 | 382 | 3 | 77 | 1,430 | |

2024 | 477 | 400 | 0.08 | 308 | 3 | 78 | 1,266 | |

Note: |

Incorporation of Innovation Technology and Facility

- FENV implemented a new chemical management strategy in 2024 by replacing the oil-based chemicals, which emitted more volatile organic compounds (VOCs) during production, with water-based versions. The replacement has lowered the emission of VOCs radically by 73%, which mitigates negative environmental

impacts. - Kuanyin Dyeing and Finishing Plant replaced a dated stenter in 2024. The new model is equipped with a more efficient filtration and emission control system, which reduces the emission of particulate pollutants and VOCs, and cuts the emission of VOCs by 37% compared with the previous year.

- WHFE installed a vacuum waste gas treatment system, which utilizes the ultraviolet photolysis method to photodegrade hazardous substances into small non-hazardous molecules. The system works in conjunction with the honeycomb activated carbon, which absorbs the photodegraded waste gas and further removes hazardous residues with its honeycomb-shaped structure to purify the air.

Supply Chain Management and Training

- FEIS invited the suppliers of automatic monitoring equipment to participate in a training course organized by the Shanghai Municipal Bureau of Ecology and Environment in 2024, and seven representatives participated.

- In 2024, the Environmental Protection Bureau made two on-site inspections at FEDZ to monitor the exhaust gas in real-time. The bureau also offered training during the visit, and four FEDZ employees participated to ensure the accuracy and efficacy of the monitoring system.