Water Resources Management

FENC water conservation implementations deliver results in the recycling and reclamation of domestic and industrial wastewater.

Water saving measures and performance

Water conservation efforts at FENC focus on reducing water loss caused by the wind drift and evaporation at the cooling tower. With production management and control, the Company aims to increase the concentration of recirculating cooling water, reduce water consumption and construct water recycling and reuse systems to achieve water conservation.The Company’s production business formulates water management plan (including water recycling system) coverage rate of 100%.

Water Conservation Project in 2024

Actual Investment | Annual Water-Saving Benefit (NT 1,000) | Water Saved | Percentage of Water Saving |

6,059 | 18,625 | 250,746 | 2% |

| Note:Water saved is calculated by before the project with the same facility and same production procedure. |

Water Recycling and Reuse

The amount of water recycled in 2024 decreased by 15% compared with 2023. The main contributing factor is lower production at the Petrochemical Business, which led to a 16% drop in the use of cooling water and a 19% decline in the reclaimed water recycled compared with the previous year. The water recycling rate rose to 99%.

Water Recycling Rate

2021 | 2022 | 2023 | 2024 | |

| Petrochemical | 98% | 98% | 98% | 98% |

| Polyester | 99% | 99% | 99% | 99% |

| Textile | 90% | 93% | 95% | 95% |

| Production Business | 98% | 98% | 98% | 99% |

Note: The water recycling rate is calculated as: total reused water ÷ (total water withdrawal + total reused water) × 100%. The calculation is based on the formula for recycling (reuse) rate, R1, in the Water Usage Plan issued by the MOEA of Taiwan. |

Reused Water Volume

Unit: megaliter

Circulating Water | Recycled Water | Total (Reused Water) | ||||

Cooling Water | Other circulating Water | Recycled Water Excluding Reclaimed Water | Reclaimed Water | |||

| Petrochemical | 2021 | 704,250 | 16,067 | 346 | 1,782 | 722,445 |

2022 | 700,497 | 14,668 | 284 | 1,140 | 716,589 | |

2023 | 598,014 | 28,352 | 169 | 1,095 | 627,630 | |

2024 | 373,795 | 27,232 | 32 | 470 | 401,529 | |

| Polyester | 2021 | 502,119 | 836 | 741 | 178 | 503,874 |

2022 | 491,856 | 859 | 660 | 210 | 493,585 | |

2023 | 480,988 | 821 | 513 | 197 | 482,519 | |

2024 | 527,377 | 831 | 539 | 238 | 528,985 | |

| Textile | 2021 | 33,106 | 0 | 1,054 | 1,776 | 35,936 |

2022 | 39,274 | 0 | 448 | 1,548 | 41,270 | |

2023 | 44,252 | 0 | 364 | 1,251 | 45,867 | |

2024 | 45,346 | 0 | 359 | 1,359 | 47,064 | |

| Total | 2021 | 1,239,475 | 16,903 | 2,141 | 3,736 | 1,262,255 |

2022 | 1,231,627 | 15,527 | 1,392 | 2,898 | 1,251,444 | |

2023 | 1,123,254 | 29,173 | 1,046 | 2,543 | 1,156,016 | |

2024 | 946,518 | 28,063 | 930 | 2,067 | 977,578 | |

| Note: 1. “Circulating water” refers to water that is used by a water consumption facility and is directly recycled and reused within said facility without being discharged. 2. “Recycled water” refers to water that is recycled and reused after being discharged out of the water consumption facility. 3. The “Other circulating Water” category under circulating water mainly includes boiler and production circulating water. 4. The water recycling rate is calculated as: total reused water ÷ (total water withdrawal + total reused water) × 100%. The calculation is based on the formula for recycling (reuse) rate, R1, in the Water Usage Plan issued by the MOEA of Taiwan. 5. The data disclosed in the table, Reused Water Volume and Water Recycling Rate, covers 100% of the FENC's major production sites of the prosuction business. |

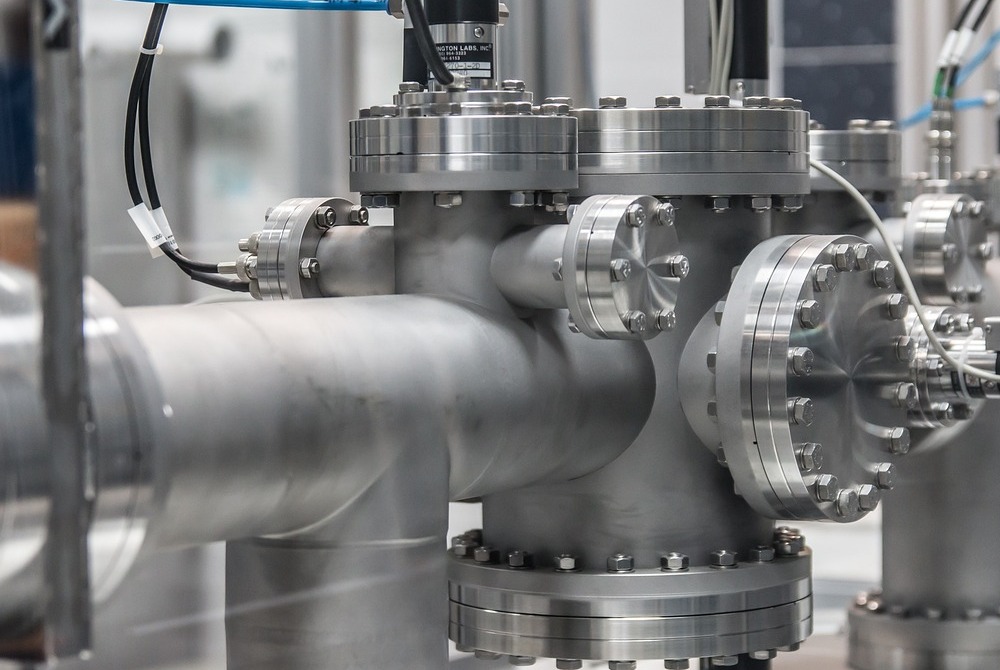

Avid Support for Governmental Policies

OPTC signed a recycled water use contract with the Taoyuan City Government for a three-phase project to utilize reclaimed water. The completion of phase one is expected in 2025 with 40,000 KL in the daily output, approximately 15,000 KL of which will be utilized by OPTC. Taoyuan North District Water Resources Recycling Center supplies the treated effluent. Once meeting the water quality standards, the effluent is reclaimed through the UF and RO membrane systems, and then sent to the industrial end users through the pipelines. This project is the exemplification of water recycling and reuse with the added benefit of preventing water shortages during the dry seasons.