Water Resources Management

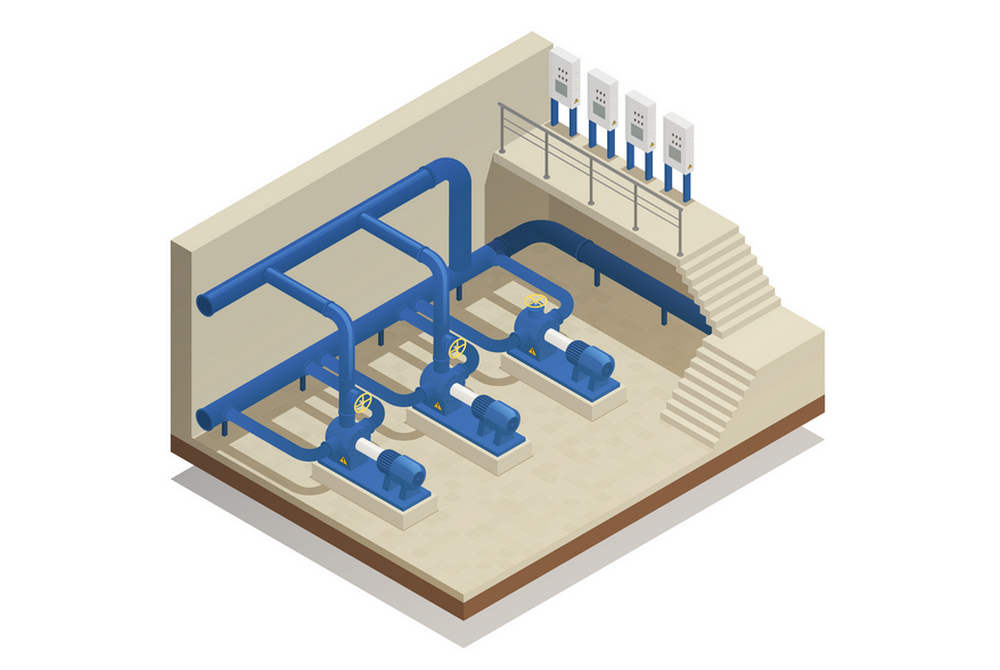

Consistently innovates and upgrades wastewater treatment facilities to reduce wastewater discharge.

Measures for Effluent Management

Effluents Management Policy

.png)

- Effluent source management

The discharge of oil agents and surfactants is minimized by modifying and optimizing the production process. - Treatment efficiency management

Gradually phase out old equipment, regularly replace filter membranes, and perform routine maintenance to prevent equipment failures in wastewater treatment facilities that could cause water quality issues and environmental impact. - Environmental impact management

Continuously establish low-noise, low-odor, and low-pollution effluent treatment facilities, fully enhance effluent recycling rates, and implement resource recycling and reuse. Use online monitoring instruments to measure and monitor the concentration of Mixed Liquor Suspended Solids (MLSS) in the wastewater treatment system. Provide real-time sludge concentration data to facilitate operator adjustments and ensure stable system operation.

FENC has a comprehensive set of guidelines and operating procedures established to address effluent discharge. The Company conducts pollutant treatment with regular self-evaluation and testing that target an array of pollutants. Among them, those regulated by the local government are prioritized for treatment to keep the water quality in line with regulatory standards. Permits are obtained from the government authority prior to discharging the effluent into water bodies as stipulated by law, and the recycled effluent is for internal use only.

Since February 1, 2023, water users in Taiwan with over 9,000 KL in monthly consumption have been imposed a water conservation charge during the dry season. After the requirement went into effect, FENC paid a yearly charge that amounted to approximately 0.1% of the total revenues generated by its production sites in Taiwan, which does not constitute a material financial impact. FENC will minimize its water conservation charge by continuing to implement water conservation measures, utilizing reclaimed water and increasing the water recycling rate.

Water Discharge in 2024

.png)

Water Discharge per Unit of Production

Unit: kiloliter / metric ton of production

.png)

The total effluent is down by 18% in 2024 compared with the previous year, and the effluent per unit of production is cut by 14%. The Company will install additional effluent recycling and reuse systems to increase water efficiency per unit of production.

Wastewater Discharge

Unit: megaliter

Water discharge by TDS | Water discharge by destination |

| |||||

Freshwater (≤ 1,000 mg/L | Other water ( > 1,000 mg/L | Surface water | Off-site water treatment | Total discharge water | Water Discharge per Unit of Production | ||

| Petrochemical | 2021 | 0 | 6,211 | 0 | 6,211 | 6,211 | 2.62 |

| 2022 | 0 | 6,251 | 0 | 6,251 | 6,251 | 3.00 | |

2023 | 0 | 5,372 | 0 | 5,372 | 5,372 | 2.91 | |

2024 | 0 | 3,516 | 0 | 3,516 | 3,516 | 2.55 | |

| Polyester | 2021 | 967 | 2,074 | 2,000 | 1,041 | 3,041 | 0.58 |

| 2022 | 367 | 2,338 | 1,702 | 1,003 | 2,705 | 0.56 | |

2023 | 330 | 2,064 | 1,341 | 1,053 | 2,394 | 0.50 | |

2024 | 1,542 | 1,083 | 1,594 | 1,031 | 2,625 | 0.53 | |

| Textile | 2021 | 847 | 2,480 | 1,849 | 1,478 | 3,327 | 6.53 |

| 2022 | 445 | 2,081 | 1,271 | 1,255 | 2,526 | 5.40 | |

2023 | 366 | 1,614 | 947 | 1,033 | 1,980 | 4.89 | |

2024 | 398 | 1,454 | 832 | 1,020 | 1,852 | 4.92 | |

| Total | 2021 | 1,814 | 10,765 | 3,849 | 8,730 | 12,579 | 1.53 |

| 2022 | 812 | 10,670 | 2,973 | 8,509 | 11,482 | 1.54 | |

2023 | 696 | 9,050 | 2,288 | 7,458 | 9,746 | 1.37 | |

2024 | 1,940 | 6,053 | 2,426 | 5,567 | 7,993 | 1.18 | |

Note: 1.FENC does not discharge effluent directly to the seawater or groundwater / well water. Please refer to the table, Effluent Treatment Methods and Final Discharge Destination. 2.The boundary of data collection for effluent discharge per unit of production for the Textile Business does not include FEAZ, FENV and FEAV. |

Effluents Treatment and Final Discharge Destination

Business | Production Site | Effluents Treatment and Final Discharge Destination |

Petrochemical | OPTC | Wastewater at Plant 1 of OPTC goes through biotreatment, including anaerobic and super deep aeration treatments and discharged into Shulin River once it meets the effluent standards. At Plant 2 of OPTC, wastewater goes through biotreatment, including anaerobic and high-efficiency aeration treatments. Once reaching the sewage connection standards, the wastewater is discharged into the sewage system operational center in Kuanyin Industrial Park and finally discharged into Shulin River. |

Polyester | Hsinpu Chemical Fiber Plant | Wastewater goes through biotreatment internally. Once reaching effluent standards, it is discharged into Fengshan River. |

Kuanyin Chemical Fiber Plant | Wastewater goes through biotreatment internally. Once reaching effluent standards, it is discharged into Shulin River. | |

FEFC | Wastewater goes through biotreatment (contact oxidation) and sedimentation internally. Once the water reaches the effluent standards, it is discharged into Shulin River. | |

OGM | Plant 1: The wastewater is treated at the effluent treatment facility within OGM. Once reaching the sewage connection standards, the wastewater is discharged into the sewage system operational center in Kuanyin Industrial Park and eventually discharged into Shulin River. Plant 2: The wastewater is treated at the effluent treatment facility within OGM. Once reaching the sewage connection standards, the wastewater is discharged into the sewage system operational center in Taoyuan Science and Industrial Park and eventually discharged into Dajue River. | |

FEIS | Wastewater is treated internally until reaching the required standards, and then discharged through the municipal pipelines to Fengxian District East Wastewater Treatment Plant. Once fully treated, the wastewater is discharged into Hangzhou Bay. | |

WHFE | Treated in the internal wastewater treatment facility first, the wastewater then goes through the municipal wastewater treatment facility. Once fully treated, it is discharged into the Yangtze River. | |

FEPV | Wastewater is treated internally until reaching the required standards (through online testing), and then discharged into ecological pond no. 1 in Bau Bang Industrial Park. Once fully treated, the water is discharged to Thị Tính River. | |

FIGP | Tokyo Plant: Wastewater is treated internally until reaching the required standards and then discharged to Tone River. Himeji Plant: Wastewater is treated internally until reaching the required standards and then discharged to Yumesaki River. | |

APG Polytech | Wastewater is treated internally until reaching the required standards and then discharged to Ohio River. | |

Textile | Kuanyin Dyeing and Finishing Plant | Wastewater is treated in house, discharged to the wastewater treatment plant in the industrial park for further treatment, and then discharged into Shulin River. |

Hukou Mill | Wastewater goes through biotreatment (oxidation and aeration) internally and then discharged into Desheng River. | |

OTIZ | Wastewater is treated internally until reaching the required standards, and then discharged through municipal pipelines to Hedong Wastewater Treatment Plant. Once fully treated, the water is discharged to the Jing-Hang Grand Canal. | |

FEIW | Wastewater goes through Wuxi municipal sewage pipelines to the wastewater treatment facility. Once treated, the water is discharged into the Jing-Hang Grand Canal. | |

FEDZ | Wastewater is treated internally until reaching the required standards, and then discharged through municipal pipelines to Hedong Wastewater Treatment Plant. Once fully treated, the water is discharged to the Jing-Hang Grand Canal. | |

FEAZ | Wastewater is treated internally until reaching the required standards, and then discharged through municipal pipelines to Chengnan Wastewater Treatment Plant. Once fully treated, the water is discharged to the Jing-Hang Grand Canal. | |

FEAV | Wastewater is treated at the treatment center within the industrial park and then discharged to Saigon River. | |

FENV | Wastewater is treated at the treatment center within the industrial park and then discharged to Song Be River. | |

FEPV | Wastewater is treated internally until reaching the required standards (online monitoring), discharged to the wastewater treatment plant in the the No. 1 ecological pond of Baopeng Industrial Zone, and finally discharged to the Thị Tính River. |

| Note: 1. There is no significant impact from wastewater discharge on the water bodies and related habitat. 2. Wastewater at OPSC includes wastewater from the manufacturing process, domestic wastewater, lab wastewater and wastewater from the cooling tower. Wastewater at Hsinpu Chemical Fiber Plant, Kuanyin Chemical Fiber Plant, FEFC and FEIS is from the manufacturing process, cooling tower, domestic wastewater and cleaning water. Wastewater at OGM, WHFE, FEDZ the polyester plant of FEPV and APG Polytech is from the manufacturing process, domestic wastewater and lab wastewater. Wastewater at Kuanyin Dyeing and Finishing Plant, OTIZ and FENV is from the manufacturing process and domestic wastewater. Wastewater at OPTC is from the manufacturing process and the cooling tower. Wastewater at Hukou Mill, FEIW, FEAZ and FEAV is from domestic wastewater. Wastewater at the textile plant of FEPV and FIGP is from manufacturing process. 3. Calculation of wastewater at Hukou Mill also includes the biomedical business unit of Oriental Resources Development Limited. 4. There is no significant impact caused by the effluent on water bodies and adjacent habitats. 5. Minimum wastewater discharge standards have been established at all production sites in accordance with local regulations and industry characteristics. 6. The discharge water treatment method and final discharge location have not changed in the past three years. |