Water Resources Management

We are targeting the management of water resources for Company sites within water risk areas and has set management goals. By gaining more understanding of the social and environmental impacts on local communities, the Company is able to respond properly and protect water resources.

Water Risk Management

FENC regularly assesses the level of water risks in areas where FENC production sites are located using the Aqueduct Water Risk Atlas from the World Resources Institute (WRI). The tool assesses the overall water risks, such as water stress, riverine flood risk as well as regulatory and reputational risks. When the overall water risk score is between 3 and 4, which indicates “high risk,” the production site is located in an area with high water risks.

The assessment conducted in the fourth quarter of 2024 identified nine FENC production sites as being located in high-risk areas, four of which are located in water-stressed areas. FENC is responding by strengthening its adaptation strategies, such as improving production water efficiency, establishing a rainwater harvesting system and increasing reclaimed water recycling rates.

Water Risk Adaptation and Mitigating Actions

Climate change has led to environmental risks such as water shortages, and FENC is responding by investing in mitigation and adaptation projects to address water risks. The Company devoted approximately NT$12 million in capital spending to avert water-related risks in 2024 with approximately NT$96.4 million appropriated in the 2025 budget.

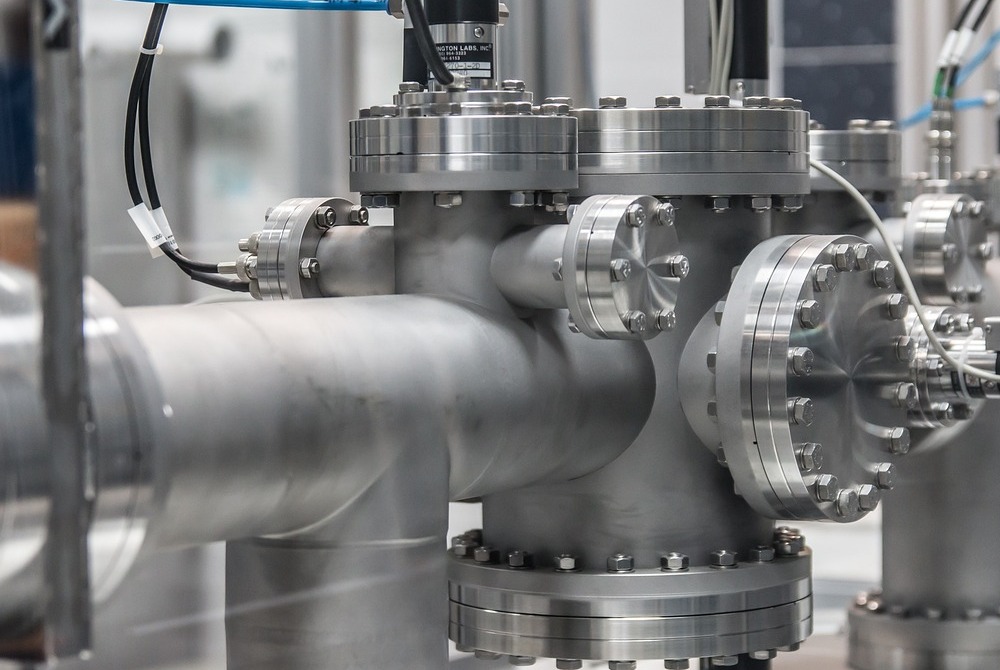

Additionally, FENC is enhancing water efficiency through multiple water conservation projects, such as lowering evaporation and wind losses from the cooling tower; increasing the concentration ratio for the water circulating through the cooling system under controlled production conditions; creating water recycling and reuse systems; recycling and reusing effluents with membrane technologies.

Water Withdrawal and Water Consumption of Production Sites Within Water Stress Zones

Unit: megaliter

2021 | 2022 | 2023 | 2024 | |

Rivers/Lakes/Streams | 0 | 0 | 0 | 0 |

Third-party Water | 1,894 | 1,594 | 1,603 | 1,511 |

Groundwater | 0 | 0 | 0 | 0 |

Rainwater | 41 | 16 | 27 | 25 |

Total Water Withdrawal | 1,935 | 1,610 | 1,630 | 1,536 |

Total Water Consumption | 542 | 397 | 468 | 428 |

Note:1. According to the Aqueduct Water Risk Atlas from the World Resources Institute, a region is considered as facing high water stress when it is withdrawing 40% or more of its available water supply annually.2.The boundary of data collection includes the four FENC production sites located in water-stressed areas. The concentrations of total dissolved solids (TDS) tested across all water withdrawal categories are equal to or lower than 1,000 mg/L. |

In 2024, water withdrawal from FENC sites in water-stressed areas was down by 6% and water consumption by 9% compared with 2023. Moving forward, FENC will continue stepping up its action towards improving water efficiency to promote reasonable water allocation and utilization.

Water Discharge of Production Sites Within Water Stress Zones

Unit: megaliter

2021 | 2022 | 2023 | 2024 | ||

| TDS | Freshwater (TDS≤1,000 mg/L) | 728 | 231 | 182 | 198 |

Other (TDS>1,000 mg/L) | 665 | 982 | 980 | 910 | |

| Destination | Surface Water | 0 | 0 | 0 | 0 |

Off-Site Wastewater Treatment Facilities | 1,393 | 1,213 | 1,162 | 1,108 | |

Total Water Discharge | 1,393 | 1,213 | 1,162 | 1,108 | |

Note: 1. According to the Aqueduct Water Risk Atlas from the World Resources Institute, an area is considered to be faced with water stress when the ratio of total annual water withdrawal to the total available annual renewable water supply is 40% or higher. |

Located in a water-stressed area, OTIZ has been implementing a slew of measures, making technological advancements that focus on avoidance and recycling, and supporting government policies. The results are noticeable. On avoidance, OTIZ has adjusted the concentration ratio of cooling water and reduced the frequency of water softening and regeneration. Recycling measures include reclaiming and reusing the concentrate generated during the reverse osmosis (RO) filtration process; adding pipelines to increase rainwater harvesting during the flood season; implementing zero discharge of production wastewater.